- New tool at The University of Manchester allows researchers to build layered van de Waals heterostructures in an ultra high vacuum environment with new library of 2D materials.

- Funding from the Royce brought pioneering research collaboration with Prevac to life.

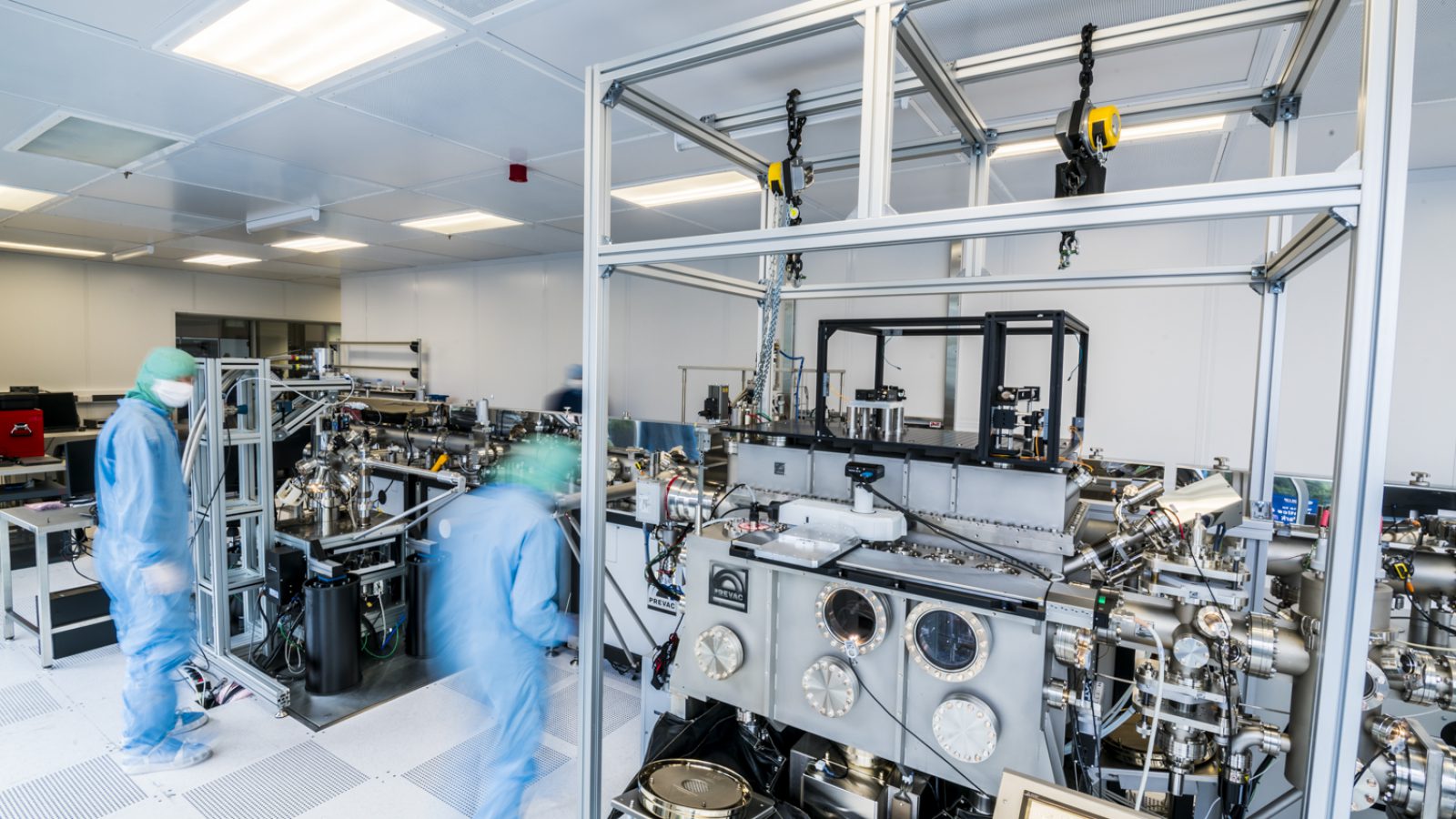

The Henry Royce Institute has enabled researchers at the National Graphene Institute (NGI) to build an Ultra-High Vacuum Suite for the nanofabrication and characterisation of 2D materials and their sandwich heterostructures, with Prevac instruments.

Following the isolation of Graphene in Manchester in 2004, researchers have discovered a whole new library of 2D materials. Since 2010, researchers have been combining these 2D materials to develop new ‘designer’ structures with unique properties and implications for future technologies.

Considerable advances have been made in streamlining the ability to analyse volatile atomically thin 2D structures, as few are stable in air.

Royal Society Research Fellow and PI for the UHV Suite, Dr Roman Gorbachev says,

‘Now we are achieving the highest purity standards by assembling heterostructures in ultra-high vacuum, where there is no chemical degradation, no contamination from air. This gives the best quality structures that we can achieve, unveiling a range of exciting physical phenomena’

The system’s interconnected chambers allow researchers to create, analyse and fabricate new layered structures. Researchers can analyse optical and electrical properties in the main UHV chamber, as well as the atomic behaviour using a built-in Scanning Transmission Electron Microscope.

“We can use hundreds of different materials and we can stack them in any combination while keeping the interfaces between them chemically clean and sharp.”

Speaking on the UHV suite’s pioneering design, Senior Experimental Officer Dr Thomas Bointon said:

‘The really unique part about this system is that it allows us to do many different processes all within the UHV environment’.

The suite demonstrates a new horizon for the engineering of 2D and layered materials enabling researchers to exploit thousands of structure combinations. Further development is underway to fully automate the system to improve the speed and reliability of analysis.

To find out more about the Ultra High Vacuum Suite and other facilities for 2D Materials research and innovation please contact:

Dr Thanasis Georgiou

Business Development Manager | 2D Materials

Henry Royce Institute