This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Research Area

Biomedical Materials

Vision

The objective of the Biomedical Materials Research Area is to accelerate the discovery, manufacture and translation of biomedical materials, enhancing the UK’s position as an international leader in the fields of biomaterials and biomedical systems and devices.

Above: watch Professor Jonny Blaker introduce the Biomedical Materials Research Area.

/

/

Medical technology has a turnover in excess of £16 billion

Introduction and Scope

Globally, the number of individuals aged 60+ is projected to reach 1.4 billion by 2030. In response to the change in the age demographic, a new generation of ‘smart dynamic’ biomedical materials are required to support novel medical approaches that sustain and improve human health and well-being for longer.

Materials for Personal Health has therefore been identified as a National Materials Challenge. Royce is able to accelerate the discovery, manufacture, and translation of these materials using national resources, expertise, and state-of-the-art facilities.

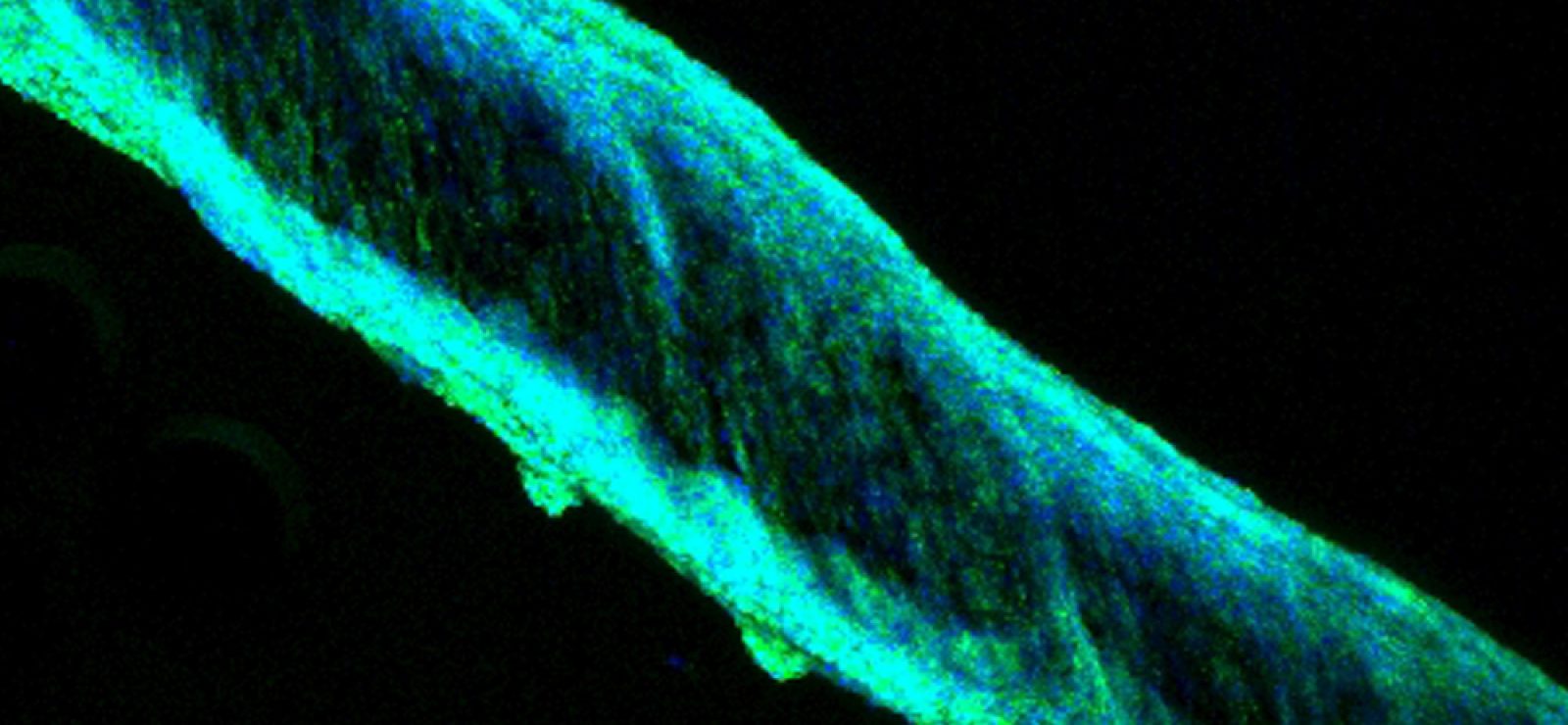

We are focussing on materials capable of mimicking the spatiotemporal dynamic, the creation of tissue mimics for simulation and modelling, creation of devices to restore biological function with minimal invasiveness, improved healing, and diagnostic tools.

We are also looking to exploit material advances in other Research areas within Royce, e.g. 2D materials and flexible electronics and apply these to neuromorphic materials.

Royce aims to accelerate the provision of affordable, advanced materials solutions to the healthcare sector.

Current and Future Research

- Biomimetic tissue analogues: Developing synthetic cell-microenvironments to study interactions and develop novel regenerative therapies.

- Additive Manufacture: Bespoke hard and soft implants towards patient-bespoke biomedical materials, devices, MRI phantoms, and tissue engineered products.

- Materials for tissue healing: Physical and chemical properties of materials are fundamental in effective tissue healing, including drug-delivery. Examples include: Vascular tissues: blood vessels and cardiac. Wound healing: skin. Respiratory tissues: lung. Nervous system: peripheral and central nervous systems. Orthopaedic: intervertebral disc, cartilage, tendon and ligament. Ophthalmic: corneal tissues.

- Bioelectronics, Diagnostics and Biostimulation:

Biosensing, monitoring and stimulation; crossing the wet-dry divide. - Materials for a safer world: Materials solutions related to PPE, filtration, the detection, spread and growth of pathogens in our environment.

- Microtissues-on-a-chip: combining microfluidics with microomics and bioprinting to develop integrated drug testing platforms enabling real-time analysis.

- Prosthetic synapses: for damaged nerve systems, using electrodes to record activity and processing by neuromorphic architectures, and the output signals fed back into the nervous system through electrical stimulation.

Links

Investment: £0.5M Wolfson foundation infrastructure investment,

£6.7M EPSRC-CDT; £0.2M Wellcome Trust IISF

Training: Advanced Biomedical Materials EPSRC-CDT (Manchester, Sheffield and Industry stakeholders). Regulatory workshops. Technical training (ImagingBioPro, Clinical Imaging).

Industry: Materials in Medicine ‘MATMED’; academic partners in five European countries, with SME contacts in each location (ERDFfunded).

International: Indian Institute of Science (IISc)-Global Challenges Research Fund. Manchester-Melbourne-Toronto collaboration.

Networks: STFC, Catapults, BioNOW, Medilink, ImagingBioPro, AMBER (Advanced Materials and BioEngineering Research).

Equipment & Facilities

The £105m, nine-story Royce Hub Building, at the heart of the University’s Engineering Campus will be home to world-leading materials scientists, £45m worth of equipment and collaborative space for industrial and academic engagement. The building design is intended to allow ‘Science on Show’ – areas of the building visible to engage people outside – while also providing closed, confidential spaces for commercially sensitive work.