This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Materials for Fusion

Developing a technology roadmap for baseline and value-added materials for fusion

Project Overview

The UK is a world leader in fusion technology and has an ambitious programme for a net positive energy spherical tokamak by 2040. The programme is at the concept stage and major opportunities exist to identify, select and develop materials systems for structural and functional requirements which will then be used in the prototype and commercial reactors.

Royce worked with the UK Atomic Energy Authority to develop a focused technology roadmap for baseline and value-add materials for fusion. The output is a clear commentary on the current strengths and opportunities, technology gaps, and investment requirements.

Project Collaborators

ROADMAP

The UK Fusion Materials Roadmap, published by UKAEA and Royce, and developed with the input of over a hundred materials experts from the UK research community and industry, highlights five major areas of work required to enable the materials for future fusion power plants.

Fusion – the same principle by which the sun creates heat and light – has the potential to be an abundant, low-carbon and safe part of the world’s future sustainable energy supply.

Recent advances in the technology mean that prototype fusion power stations are now being designed, with the UK’s STEP plant due to go online in the early 2040s.

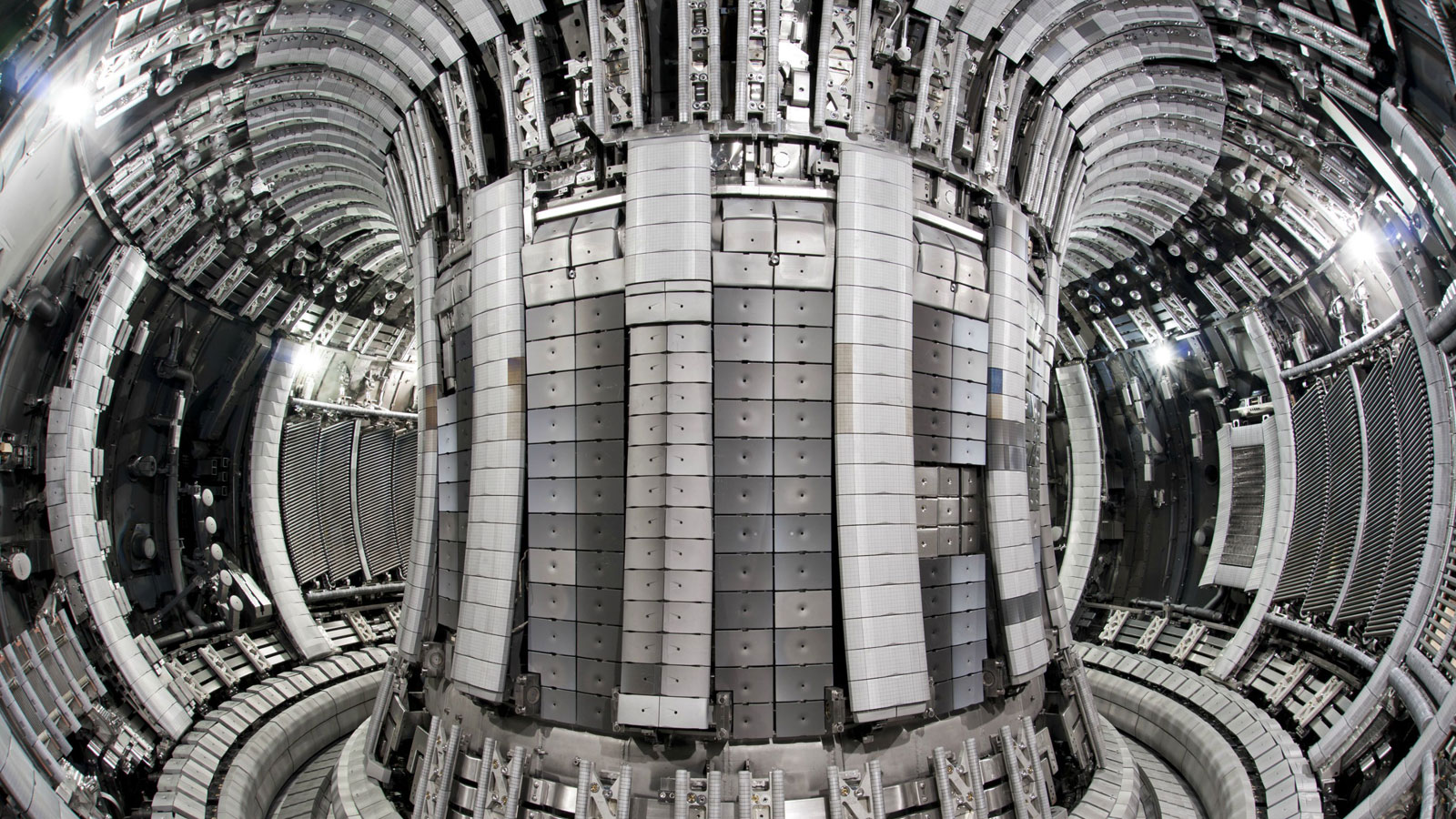

The leading contender for fusion power plants is the ‘tokamak’ – a ring-shaped machine in which fuel is confined with powerful magnets and heated until particles fuse together. The fusion process produces high-energy neutrons that can be turned into electricity, but which also significantly damage and irradiate materials within the device.

Identifying, developing and qualifying the right materials is key to delivering commercial fusion for two reasons. First, plant efficiencies, safety and availability often hinge on the quality of the component materials. Second, a sustainable fuel cycle requires highly productive fuel breeding materials. Both plant components and fuel breeder materials will need to withstand a highly challenging combination of neutron bombardment and thermal, magnetic, electric and mechanical loads in a tokamak power plant.

The five priority areas identified by the UK Fusion Materials Roadmap are:

- Novel materials to minimise the amount of activation in the structure of the fusion power plant;

- Compounds that can be used within the power plant to optimise breeding of the tritium fuel to sustain the fusion process;

- Magnets and insulators that are resistant to irradiation from fusion reactions – especially under cryogenic conditions;

- Structural materials able to retain their strength under neutron bombardment at high operating temperatures (over 550 degrees C);

- Engineering assurance for fusion materials – providing irradiated sample data and modelled predictions such that plant designers, operators and regulators have confidence that materials are suitable for use in future commercial power stations.

“This roadmap is a national tool that aims to give UK materials researchers common themes to collaborate around. We hope to generate momentum in the testing, mechanistic understanding, and surmounting of, irradiation damage from fusion.

“The roadmap is also a teaching document for those who wish to learn more about fusion materials from a supply chain and regulatory point of view.

“It will help to form new partnerships across a wide range of materials stakeholders so we can bring fusion electricity to the world as quickly as possible.”

“

Roadmapping Process

Through a series of workshops between February and April 2021, we are brought together the materials supply chain, nuclear engineering specialists, academia and the broader parastatal community to outline R&D trajectories for fusion materials design, manufacture, testing, qualification and specification for the period 2020-2040.

The scope of the project includes commercially feasible materials capable of radiation resilient performance, low- to intermediate-level waste outcomes, and value engineering used in a magnetic confinement fusion reactor and its radiation shield. We excluded civil structures and anything outside the reactor building not exposed to radiation.

Project Team