- The University of Sheffield working with Tri-Tech 3D to install latest Desktop Metal Studio Systems

- New system enables printing of a wider range of components to higher resolution finishes at reduced costs

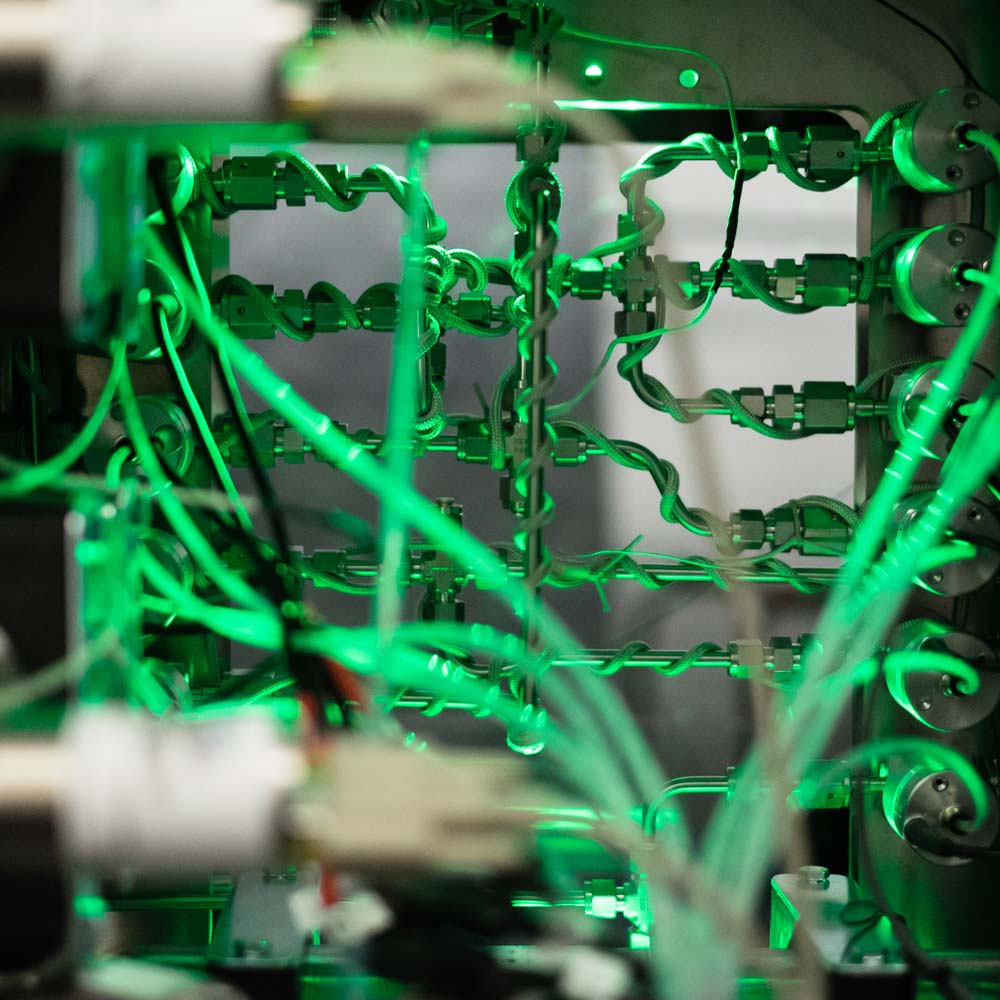

- Desktop Metal Studio System provides on-demand metal 3D printing that can deliver scale and flexibility for diverse engineering needs

The University of Sheffield has become one of two UK organisations to implement the New Desktop Metal Studio System. The Studio System is designed to provide an office-friendly metal 3D printing solution that can allow for rapid prototyping at low volume and cost while providing users with the ability to efficiently produce tooling, jigs, and fixtures, features which were previously cost-prohibitive.

The Studio System has already had a major impact on the additive manufacturing arena, with companies such as Ford, Google ATAP, Goodyear, BMW Group, John Zink Hamworthy Combustion and ProtoLabs, all becoming early adopters of the platform and attracting encouraging interest from fast followers.

The University of Sheffield is working with the Tri-Tech 3D team to install their Desktop Metal Studio System at the Royce Translational Centre.

Prof Iain Todd, Royce Translational Centre’s Director commented:

We at Royce@Sheffield are very excited to receive our Desktop Metal Studio System. Additive Layer Manufacturing (ALM) is a critical part of the strategy for many high-value manufacturing sectors, as they look to reduce material waste and increase productivity. ALM covers many technologies, and with the Studio System, we are expanding our set of advanced 3D metal printers, which already includes electron and laser beam powder beds, and blown powder methods. Our industry partners range from start-ups to multinational aeronautical manufacturers: for them we represent a valuable missing link between small-scale laboratory metals processing and industrial scale manufacturing. The Desktop Metal Studio System keeps us at the cutting edge of near-net shape manufacturing capabilities in the UK.

Weir Group Head of Additive Manufacturing – Sozon Tsopanos, commented:

The additive manufacturing arena is dynamic, growing rapidly as a market, and presents exciting opportunities for innovative companies such as Weir. We are continuing to partner with world-class organisations as we proactively develop our additive manufacturing offering. The addition of this versatile system complements our existing capabilities at Weir Additive Manufacturing Solutions, allowing us to explore, prototype, test and commercialise components and tooling that will deliver significant benefits for our Mining and Oil & Gas customers globally.

For further information on the installation of the Desktop Metal Studio Systems and when it can be accessed by industry and academia contact:

Bethany Craggs

Marketing and Communications | Royce@Sheffield

E: b.n.craggs@sheffield.ac.uk