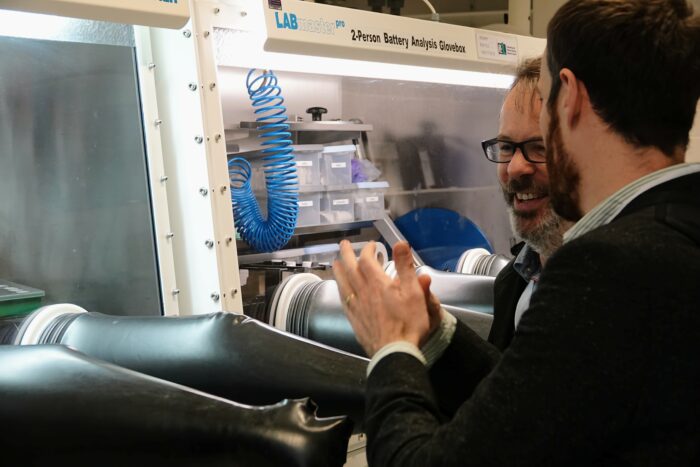

Last month saw the opening of the new Royce Battery Suite at the University of Cambridge. This comprehensive suite provides equipment for academic and commercial researchers to manufacture and process new safer, efficient and long-lasting battery materials.

By accommodating a variety of materials and overcoming difficult processing operations the Battery Suite bridges the gap between innovation and industrial collaboration. The processing operations include; microwave manufacture, digestion, separation, drying, purifying, mixing, and washing. It’s provision accelerates the transition from early-stage discovery to impact. It allows researchers to investigate scalability of their materials and whether they can be safely processed. This will provide a new capability to the energy materials community.

Last month over 100 researchers, academics, students and industry representatives attended the launch of the new Royce Battery Suite and toured the facilities at the University of Cambridge’s Maxwell Centre.

The opening was commemorated with a Symposium attended by over 100 prominent battery academics, spinouts, and industry from around the UK. Sai Shivareddy, CEO of Nyobolt spoke about how to take a novel material from research to commercialisation. Emma Kendrick, Professor of Energy Materials at the University of Birmingham explained the criticality of battery materials. Jeremy Wrathall, CEO of Cornish Lithium announced his plans for battery minerals exploration in the UK.

If your research interests require use of the Battery Suite or you have any questions on the suite’s capabilities and would like to discuss your experimental needs, contact Academic lead Dr Ismail Sami (is448@cam.ac.uk) or Facility Manager Dr Peter Knight (pjkk1@cam.ac.uk) in the Department of Materials Science and Metallurgy.

The suite includes;

Manufacturing, Digestion, Purification: Equipment: Milestone flexiWAVE microwave synthesis system and Analytix, Rotary evaporator. Description: microwave reactor for large capacity synthesis and digestion, Classic glassware – 500mL, 1 bar, High-pressure – 15 x 100mL vessels, 100 bar, Solid-phase – 500ml, 15mba, 230oC evaporator, 20-300RPM, 5L capacity, vacuum controller and pump.

Separation: Equipment: Beckman, Avanti JXN-26 centrifuge. Description: High-throughput sample processing. Centrifuge – Maximum capacity of 6.0L, 26,000 RPM, 82,000 x g. Rotor 1 – JA25.50 fixed angle, 8 x 50mL, 25,000 RPM, 75,600 x g. Rotor 2 – JLA-8.1000 fixed angle, 6 x 1000mL, 8,000 RPM, 15,970 x g

Mixing: Equipment: Intertronics, Thinky ARV-501. Description: Plantetary centrifugal slurry mixer. Maximum capacity 700g. Standard container 500mL resin. PU-501 built-in vacuum pump unit

Stirring and Drying: Equipment: IKA, Agitator and BUCHI Lyovapor L-200. Description: Large-volume shear mixing and freeze drying. T 50 digital ULTRA-TURRAX, 0.25-30L, 600-10,000 RPM. Mobile trolley, vacuum pump Edwards nXDS6iC, drying chamber manifold, -55°C, 6 kg