This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

The effect of fusion plasmas on the microstructure and thermochemical properties of tungstentantalum alloys

University of Sheffield

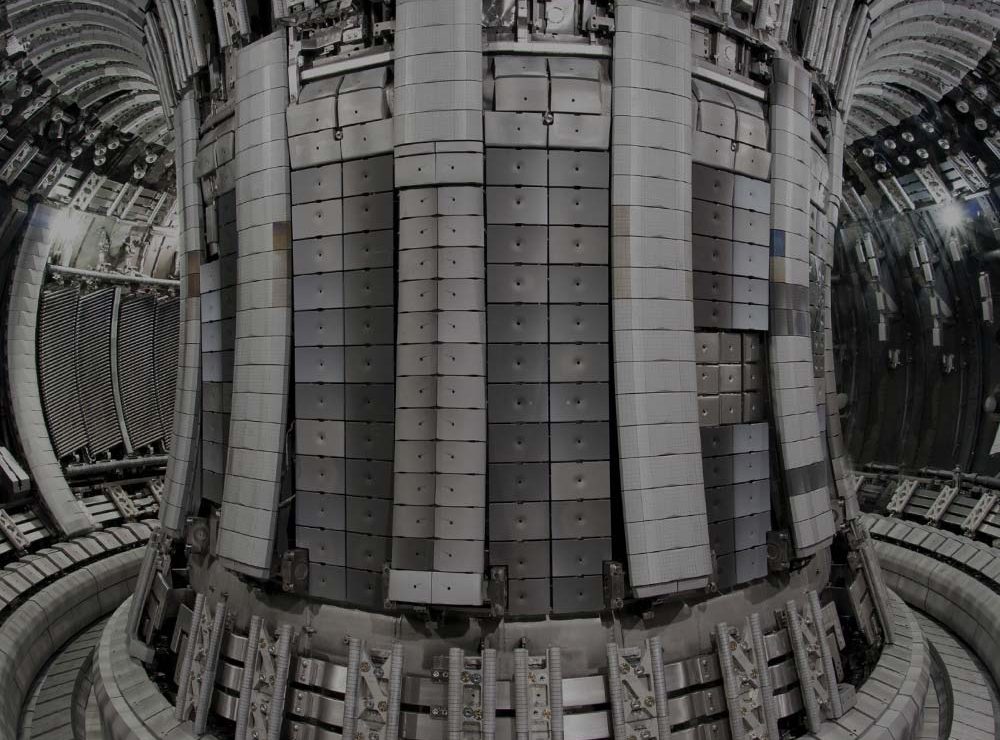

A project has been carried out using the University of Sheffield’s Arcast 200 Arc Melter to produce tungsten-tantalum alloys in complete solid solution using a novel processing method. This will now be used as the focal point of research to investigate the effect of a nuclear fusion environment through helium plasma exposure and helium ion irradiation.

Emre Yildirim, Postgraduate Researcher at the University of Manchester’s Materials Performance Centre, accessed the Arc Melter through the Royce Student Equipment Access Scheme which provides funding for research students to utilise equipment and learn new techniques to support their research. Expertise to identify what equipment and techniques would benefit Emre’s research were provided by Royce Research Associate at The University of Sheffield, Dr Yunus Azakli.

Project summary

Initially weighed and cleaned at the University of Manchester, alloys of tungsten-tantalum of weight percentage W-5%Ta and W-10%Ta in three buttons of 3.5cm2 were melted at the University of Sheffield, using the Henry Royce Institute’s Arc Melter (Arcast 200). These buttons will be integral to experimental studies. They will be exposed to helium plasmas and utilised in ion irradiation studies in order to discern the effect of helium fusion plasmas on the microstructure and thermomechanical properties of tungsten tantalum alloys.

Further research

Further measurements of the induced microstructural changes will be taken through Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM), with measurements of the thermomechanical properties before and after the experiments taken using transient grating spectroscopy. These will be further modelled through molecular dynamics simulation in order to understand why there are changes upon the addition of tantalum to a tungsten matrix. The hope is that the tantalum, which has been shown to mitigate other issues induced by a fusion environment, such as the segregation of transmutation products, will also act to inhibit some of the changes in thermomechanical properties induced by radiation damage. These samples will form the centrepiece of the experiments carried out during the project and will have a huge impact on this research.

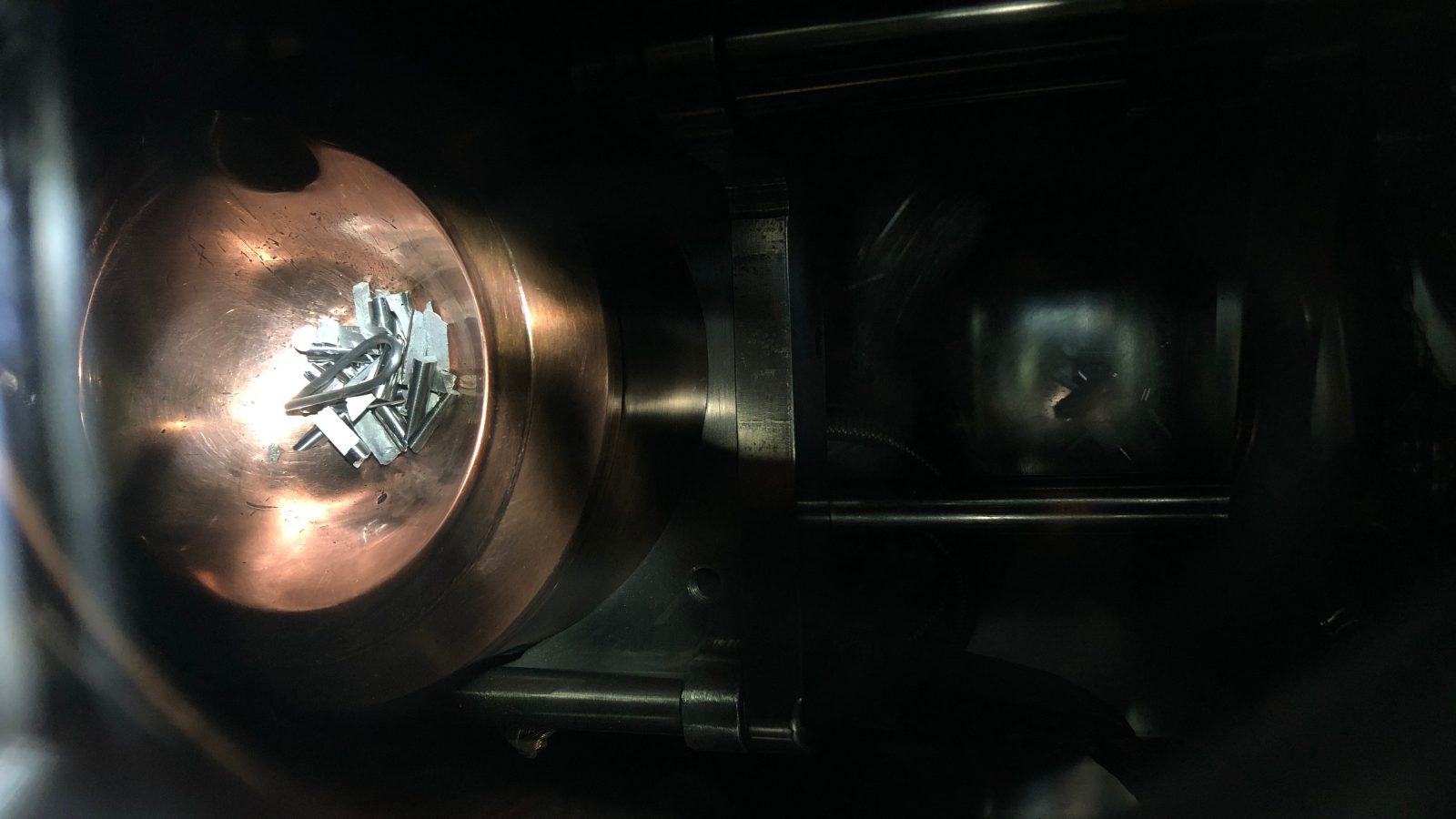

About the Arcast 200 Arc Melter

The Arc 200 vacuum arc melting furnace is a tool for research and prototype production. It offers the ability to melt, cast and rapidly solidify metal alloys of nominal 200g mass using a clean, ceramic free cold crucible process. It has the ability to melt and alloy metals at over 3000°C, such as titanium alloys, shape memory alloys, amorphous alloys and high entropy alloys.