This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Characterising materials to understand & enhance the performance of insulation systems across aerospace and automotive

Investigating the thermal, mechanical, and dielectric properties of various insulation systems used in aerospace and automotive applications.

The Royce Engineering and Physical Sciences Research Council (EPSRC) funded Industrial Collaboration Programme (ICP) has successfully matched companies that have research, development, and innovation (RD&I) projects with Royce experts in materials science and cutting-edge facilities in a truly collaborative endeavour.

This case study illustrates the outcome of an ICP project between aerospaceHV and Royce at the Universities of Liverpool and Manchester.

ABOUT THE COLLABORATION

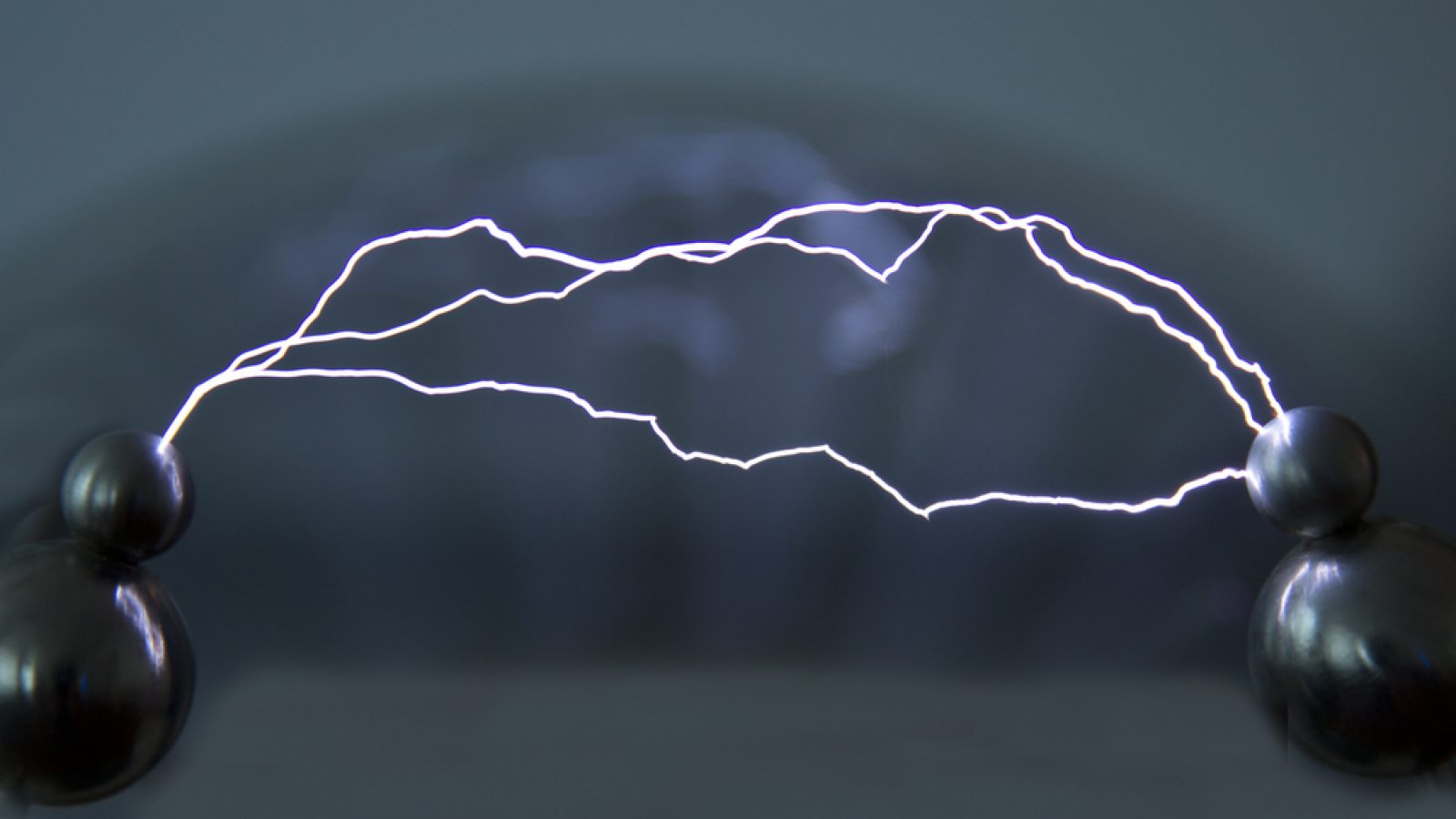

Electrification of transport demands the increased use of high voltage systems, placing higher demands on the insulation deployed within challenging environments.

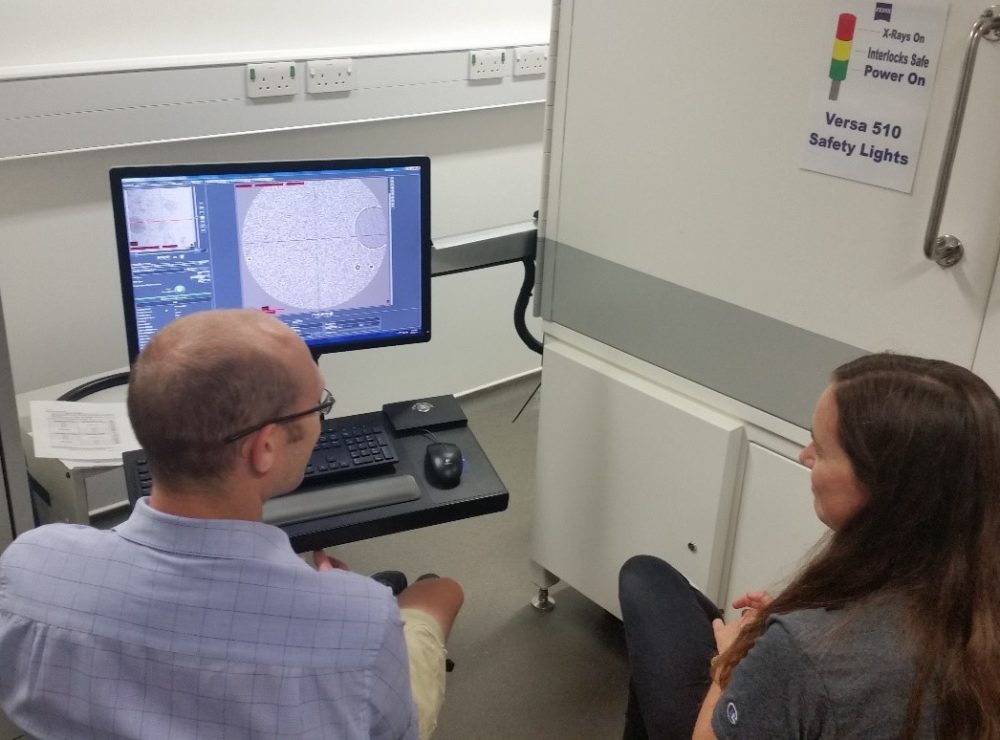

In this collaboration, aHV used their own facilities to age various types of insulation systems including those used in electrical machines and cabling systems. The items tested included samples insulated with high performance polymers Kapton (polyimide), Polyether ether ketone (PEEK) and PAI. These were then supplied to Royce alongside new, unused and untested samples for control. Royce undertook a campaign of characterisation of both these unaged and aged samples utilising a suite of different analytical capability including X-ray Computed Tomography, Gas Chromatography-Mass Spectrometry, Scanning Electron Microscopy and tribology (hardness testing). Royce was able to provide a detailed analysis and comparison of the insulation materials when used and when new.

RESULTS

Royce was able to accurately locate and image failure locations caused by electrical failure and was further able to characterise the by-products from the degradation reactions caused by gradual thermal and electrical ageing. As a microbusiness, aHV do not have the facilities required to carry out these characterisation activities; as such, Royce was able to provide a comprehensive access offer via its unique partnership model, ensuring appropriate expertise was used where required.

aHV is focused on the development, design and test of insulation systems for use in electric vehicles – essential for the development of the electric motors, cabling, connectors and power converters that are used in these systems. The collaboration means that aHV have gained a greater understanding of the techniques that can be used to evaluate the performance of insulation systems and through Royce can enhance the offer that they make to industry partners.