This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

From Romans to the industrial revolution: a story of iron and steel

Metals: Pioneering Materials

Progress in manufacturing techniques for iron through the Middle Ages (500 -1500 AD) led to this metal becoming one of the most important materials of the era, replacing the use of materials commonly used through the Metal Ages and expanding the applications of metals used in society.

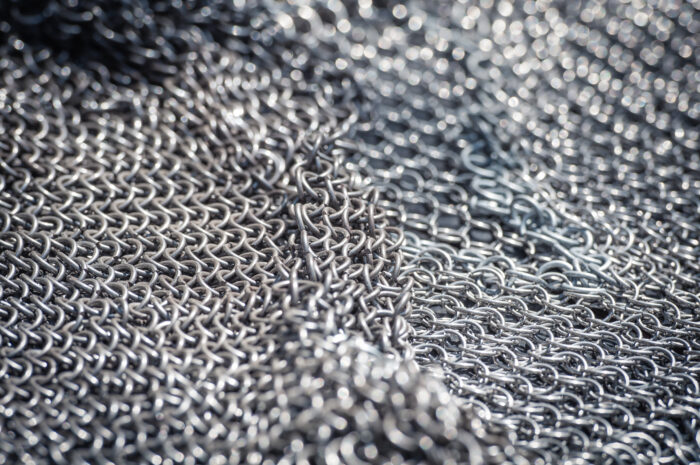

For over two thousand years (after its earliest recorded use during the Metals Ages), the most common type of iron available was called wrought iron. Wrought iron is an iron alloy with a very low content of carbon (less than 0.08%). Initially, this type of iron was created by heating and then shaping the metal with a hammer when it was softer to expel the impurities in a long process made by skilled blacksmiths. This is the reason why it was called ‘wrought’ which means ‘worked’. As early as 200 BC (about 2,200 years ago) in Asia, wrought iron started to be produced at scale in forges and commercial production was then introduced to Europe in the late medieval period. Although wrought iron is a highly malleable and ductile1 metal, its production process was long and complex. As a result, wrought iron was initially used in small quantities and later mostly used to make weapons, armours, and then later to create the first railway tracks.

Ironbridge, the world’s first iron bridge was erected over the River Severn in Shropshire in 1779

Another type of iron, cast iron, appeared in ancient times in China (as early as 500 BC – about 2,500 years ago) but did not become widespread in Europe until the late medieval period. From the 1300s, the invention of the blast furnace and casting process led to iron being produced on a much larger scale. The high temperature of a blast furnace made it possible to completely reduce iron ore, and then cast it into moulds to create cheap and standardised items. These new manufacturing techniques led to cast

iron being used in cannon balls and then as a structural material in bridges, buildings and railways. Cast iron is, however, an alloy of iron which contains a relatively high amount of carbon (over 2%) making it a brittle material which is unsuitable for items subject to powerful impacts and regular stress. This is the reason why a cast iron railway bridge collapsed under its own weight on the Chester and Holyhead Railway in the Dee Bridge disaster of 1847.

In search of a tougher metal, humans created steel. Steel is another iron alloy that contains a relatively low amount of carbon (less than 1.5%)5. Steel has existed since ancient times, made either deliberately or accidentally, but it remained very hard to produce for many centuries. The earliest evidence for steel manufacture can be traced back as early as 400 BC (about 2,400 years ago) in Asia. The specialist knowledge needed to make steel did not become widespread and steel manufacturing was limited to a small number of sites.

During the European “Age of Enlightenment” in the 1700s, a new manufacturing method called the Huntsman process (named after its inventor), made it possible to produce a stronger and more resistant metal: crucible steel. This was produced by using a fired furnace capable of reaching temperatures over 1600°C, far hotter than any blacksmith’s forge.

By the 1800s another new manufacturing approach – the Bessemer process – allowed the first mass production of steel at a much lower cost. This process removed the excess carbon and impurities by blowing hot air through the molten iron in a controlled manner within the blast furnace. This led to the industrialisation of steel and its use in buildings, ships, and machinery.

Due to its enhanced properties and low cost, steel is now one of the most used metals in the world.

Chain mail is a type of armour that was commonly worn in the Middle Ages, consisting of small iron rings linked together to form a protective mesh

Footnotes

1. A malleable material can be easily formed by hammering. In contrast, ductility is the ability of a solid material to deform without fracture.

2. The big difference between cast iron and steel is the percentage of carbon present. Carbon appears completely in its combined form in steel as iron carbide, whereas in cast iron it may appear as graphite, iron carbide or both.