This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Validating novel silver technology for a greener, wasteless future

Researchers at clean-tech start-up Metalchemy are benefiting from Royce’s advanced characterisation equipment to validate its ground-breaking technology.

About the Collaboration

Food waste is a major source of carbon emissions globally. One-third of all food production is wasted, amounting to $1 trillion in lost revenue and 10% of global greenhouse gas emissions. To balance the CO2 emissions from this food waste alone, 8.15 billion trees would need to be planted! In fact, only 34% of the food wasted in the UK would be required to feed more than 2 million individuals who cannot afford to eat, a pressing issue globally.

This is where Metalchemy technology comes into play. As a high growth, UK-based, clean-tech start-up, the company is focused on developing solutions to reduce food waste, resulting in both economic and environmental savings. Incorporating Metalchemy’s silver technology into food packaging materials delivers superior antimicrobial properties, improved barrier characteristics, and enhanced thermal stability.

The rolling out of this promising technology would see reduced food waste across the UK, with Metalchemy’s research suggesting that food shelf life can be increased by 7 days for meat, 5 days for cheese, and 4 days for fresh salad.

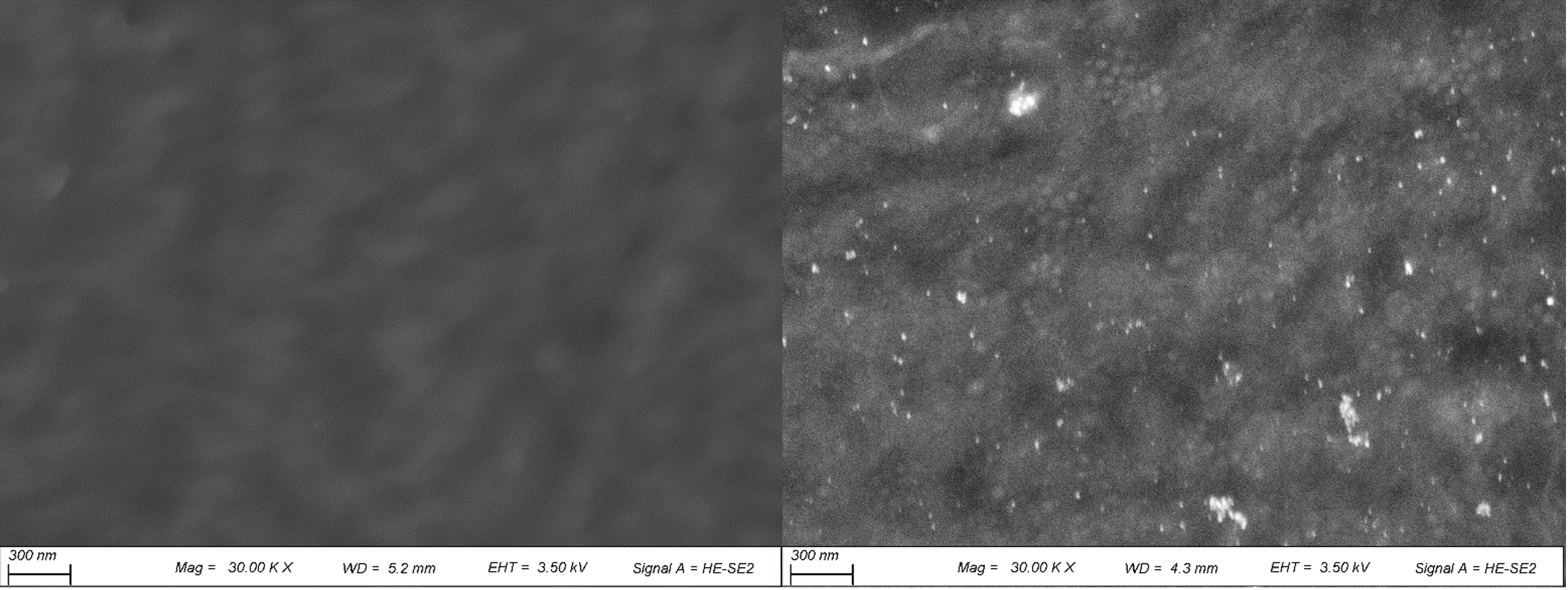

Control Packaging – (L) Control vs (R) Metalchemy Treated. We can observe the successful incorporation of Metalchemy technology on the packaging surface which allows for food shelf life extension. Secondary electron images captured using Zeiss Merlin FEG-SEM.

Control Packaging – (L) Control vs (R) Metalchemy Treated. We can observe the successful incorporation of Metalchemy technology on the packaging surface which allows for food shelf life extension. Secondary electron images captured using Zeiss Merlin FEG-SEM.

ROYCE SUPPORT

Through the Royce SME Equipment Access scheme Metalchemy was able to undertake important characterisation to assess the adherence of integration methods in packaging materials. Both treated and control samples were analysed at Royce at the University of Manchester, using Scanning Electron Microscopy and Energy Dispersive Spectrometry (EDS).

Through these advanced product characterisation techniques the team was able to detect and identify properties on Metalchemy’s packaging materials, verifying the technology’s successful integration within the material matrix. Royce was able to provide extensive and accurate imaging of packaging samples, resulting in positive findings and supporting Metalchemy’s material development goals.

RESULTS

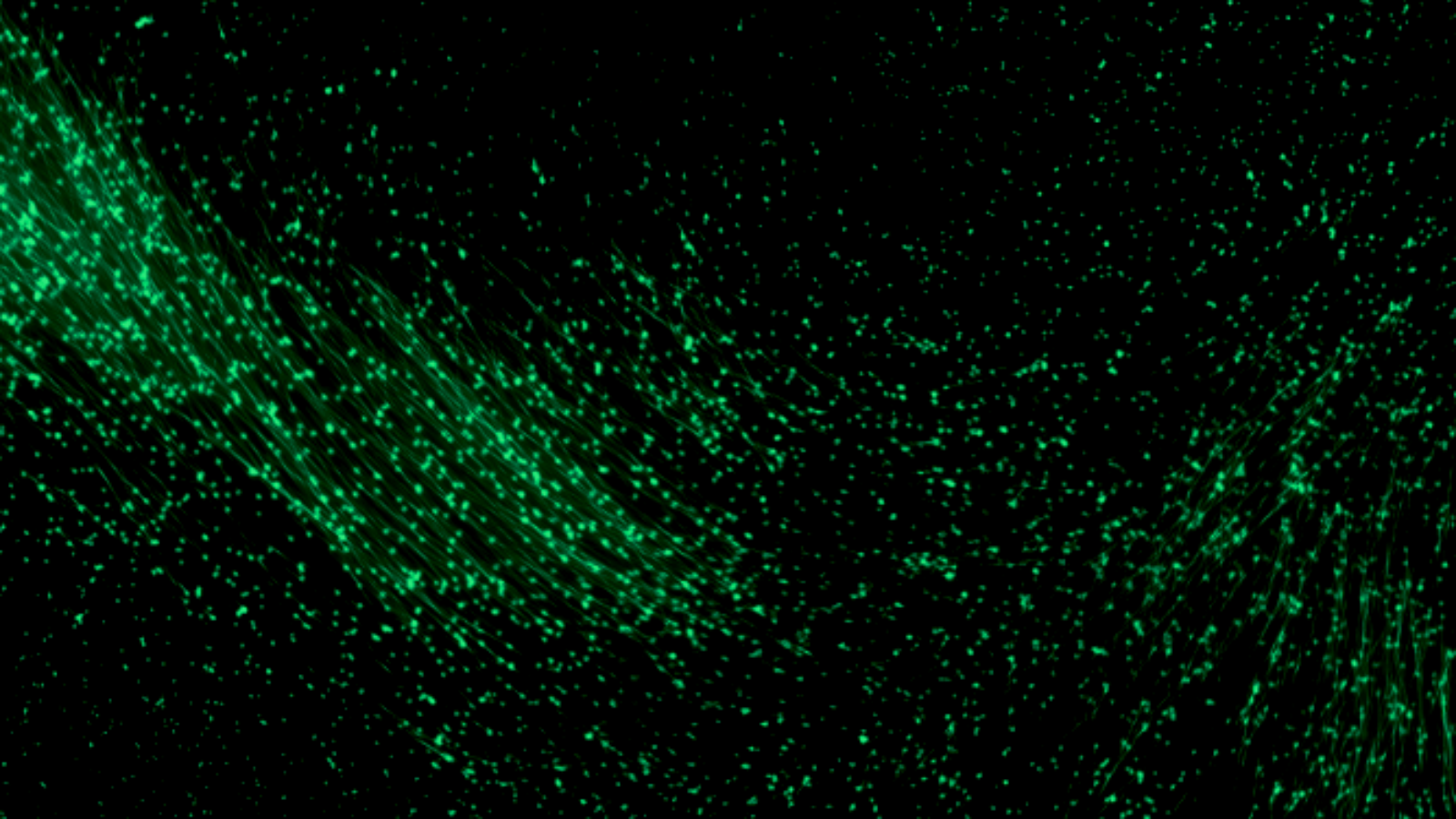

With EDS confirmation of silver components, Metalchemy and Royce were able to accurately detect the presence of a homogenous distribution of the company’s patented silver technology in several sections of the sample, as presented in figure 1. Such visual and analytical validation of materials is critical for start-ups; for Metalchemy the Royce access scheme is of real benefit, as the equipment required to carry out such analysis is both expensive and access is often limited.

Metalchemy’s work with Royce not only enabled it to confirm the successful incorporation of its silver technology in packaging materials, it will also assist in demonstrating all-important food safety and regulatory compliance, providing the technology with a clear route to market.

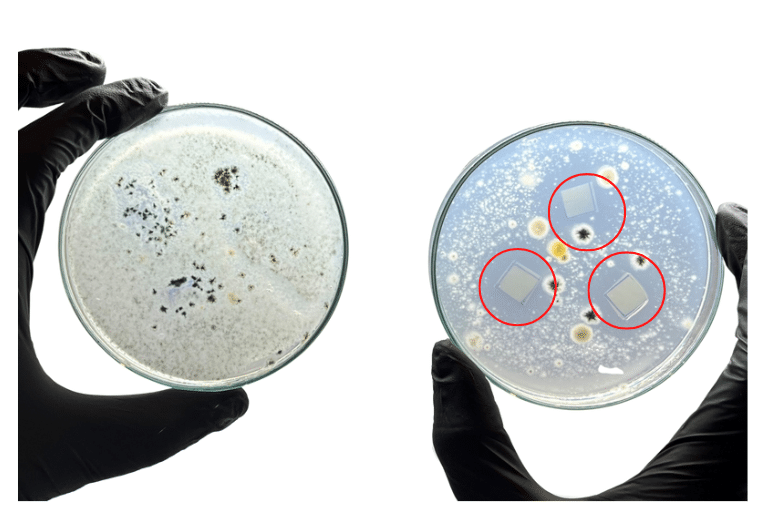

Metalchemy Laboratory testing using iso standard methodology (ISO 16869:2008) comparing Metalchemy treated packaging with and without our patented technology evaluating microbial growth inhibition. The left shows food packaging with no treatment with exhibit full microbial growth, whereas right shows no microbial growth over bioplastics incorporating Metalchemy silver technology, resulting in better preservation and microbial inhibition.

FUTURE IMPACT

Food packaging is Metalchemy’s first target market and this study has enabled Metalchemy to take an important step forward in the fight against carbon emissions and waste in the UK food industry. Its technology holds huge potential in ending food waste and successfully translating UK advanced material research into commercially viable products for the benefit of society.

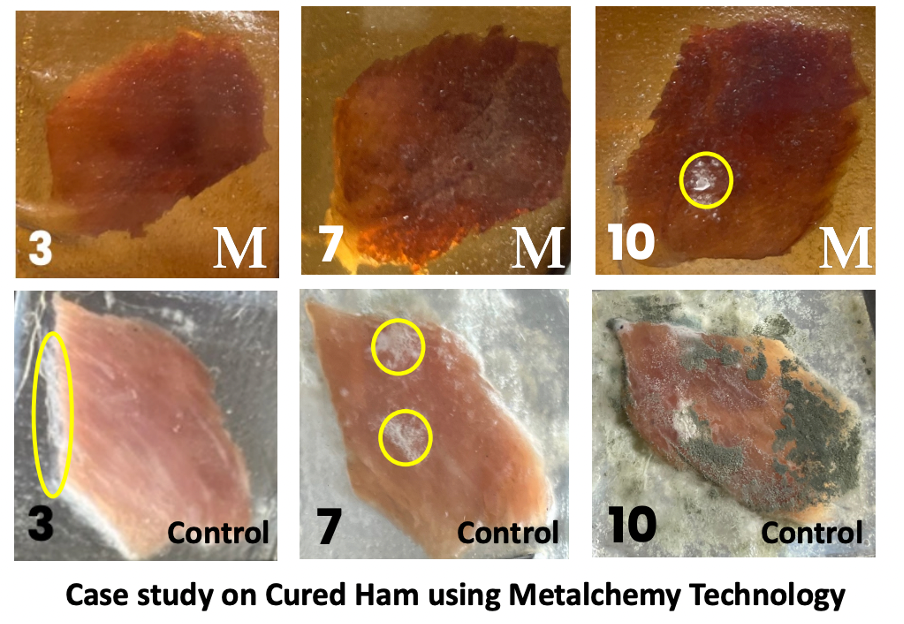

Food preservation is enhanced by using Metalchemy technology. No microbial growth was observed on Metalchemy treated packaging after 7 days, with first traces observed after 3 days on control samples. Macroscopic Microbial growth circled in yellow. From a laboratory preliminary study shelf life of Cured Ham could be increased by up to 4-7 days by using Metalchemy packaging technology by enhancing antimicrobial and barrier properties of the packaging material. Metalchemy packaging dyed in brown to enhance visualisation (top) and control packaging (bottom) as transparent material.

Food preservation is enhanced by using Metalchemy technology. No microbial growth was observed on Metalchemy treated packaging after 7 days, with first traces observed after 3 days on control samples. Macroscopic Microbial growth circled in yellow. From a laboratory preliminary study shelf life of Cured Ham could be increased by up to 4-7 days by using Metalchemy packaging technology by enhancing antimicrobial and barrier properties of the packaging material. Metalchemy packaging dyed in brown to enhance visualisation (top) and control packaging (bottom) as transparent material.

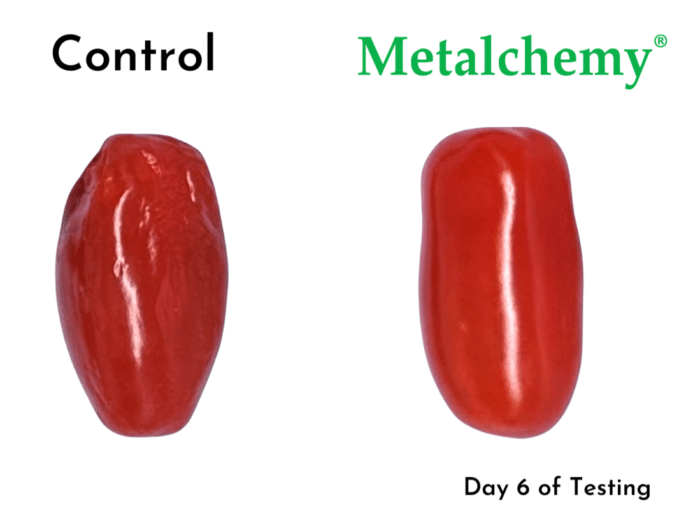

Food preservation is enhanced by including Metalchemy technology. Non-Protected Control (L) vs Metalchemy Technology (R) results prove better preservation of tomatoes.. Metalchemy protected tomatoes had a x1.6 shelf life increase on average providing for an immediate & future solution to food shortages, reduced waste and increased revenues for food businesses.

“Through our patented silver technology, we can produce enhanced packaging materials which can extend food shelf life with superior properties at a fraction of the cost of current manufacturers. This results in lower costs for businesses and consumers complemented by our green credentials, which allows us to tackle the food waste crisis with our transformative proprietary technology. According to our modelling, Metalchemy has the potential to significantly reduce food waste globally, for example by saving the UK household up to £700 per year, food businesses up to £4.5bn per year and reduce up to 25 million tons of CO2 emissions, in the UK alone. Commercially, we surveyed over +50 local food businesses, with over +40 interested, +15 very interested, and managed to sell +8000 units of our sustainable packaging & delivering it to local businesses in under 2 weeks. Currently Metalchemy also supplies the UK with local sustainable packaging, on top of developing & going to market with high-tech food waste reducing technology delivering impact at every scale.”

Federico Trotta, Founder & CEO of Metalchemy

Find out more about Metalchemy here