This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Mechanical Assessment of Aerospace Engine Materials in Hydrogen

Case Study

Royce’s Industrial Collaboration Programme (ICP) awarded a total of £120,851.67 to this project which developed and validated new testing and analysis to assess materials performance using Royce facilities.

The UK government 10 Point Plan for a Green Industrial Revolution, and Jet Zero pushes forward the goal of sustainable air travel. The transition to alternative energy sources from today’s kerosene is regarded as one of the main technology priorities, and hydrogen is one viable fuel that could power aircraft in the next 10-15 years. Particularly, the development of a hydrogen-fuelled gas turbine has been identified as a key enabler for zero carbon emission flight, as gas turbine powered aircraft currently account for 96% of today’s aviation carbon emissions.

This work pilots Royce Institute facilities for the assessment of H2 effects and establishes a UK leading capability which can continue to support the development of materials technologies for a hydrogen powered aerospace industry and the wider hydrogen powered economy (energy, automotive and transportation sectors), all of which support the ambition of Net Zero for 2050. Key outputs from this work are:

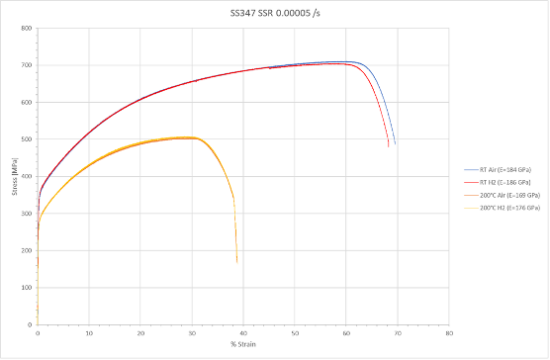

- Figure 1 shows data from slow strain rate tensile testing of SS347 in both air and pure hydrogen. There was no difference in performance at 200°C but a very slight reduction in ductility in hydrogen at RT.

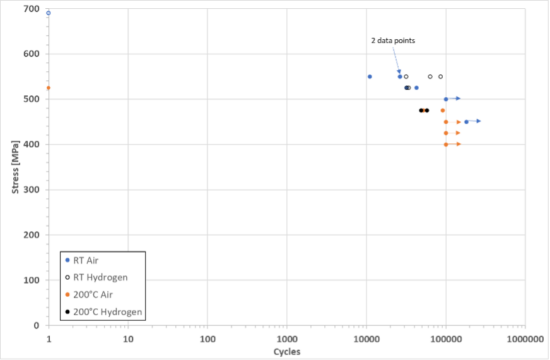

- Figure 2 shoes results from fatigue testing in hydrogen and air. Again, there is essentially no difference at 200°C but interestingly a slight difference at RT at 550 MPa peak stress, possibly linked to reduction in ductility.

- New Royce hydrogen-fatigue facility validated.

This project was designed to act as a feasibility study to prove Royce Institute partner’s capabilities in testing and characterisation in hydrogen. As a result, these facilities will be included as a sub-contract under the new £14.77M HYEST programme. It is alos expected that the project will generate interest within Rolls-Royce for additional use of the Royce Institute access scheme for use of equipment from successful dissemination of the results of this research program.

“This work has been instrumental in the validation new Royce facilities for materials certification in hydrogen, an area that is much needed within the UK and the larger community.”

Simon Gray, Cranfield University, Principal Research Fellow and TPL

Collaborators

The project took place at the new validated hydrogen-fatigue testing facility at Cranfield.

FURTHER INFORMATION

- Total funding awarded £120,851.67

- Cranfield University £72,879.74

- Manchester University £47,971.93

- Rolls-Royce Plc were a partner, but no costs were claimed from Royce.