This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Demonstrating the benefits of room-temperature field-assisted crystallisation to deliver superior protection for Al alloys

CORUNDUM PHASE EXPANDS APPLICATION POTENTIAL OF ANODISED ALUMINIUM

Researchers from Royce, Polytechnique Montréal and Cardiff University worked in collaboration with UK based SME Cambridge Nanolitic to demonstrate the benefits of room-temperature field-assisted crystallisation for turning amorphous anodic alumina into hard and stable corundum coatings that will offer a superior protection for Al alloys

BACKGROUND

Performance of aluminium alloys in harsh conditions inherent to the aerospace and transport industries rely on the protective ability of surface oxide films that are commonly formed through electrochemical anodising treatments carried out in strong acidic solutions. However, due to its amorphous structure, anodic alumina possesses insufficient mechanical properties and chemical stability, which drastically limits the application range of Al alloys. Crystallisation of the amorphous coating material converting it into hard and stable α-Al2O3 phase called ‘corundum’ presents a notable performance enhancement strategy for anodic oxide films, but this requires temperatures higher than the melting point of the alloy itself.

RESULTS

A team of researchers led by Dr Aleksey Yerokhin used the state-of-the-art electrolytic plasma processing facility and unique materials characterisation equipment available through Royce to undertake the project. Use of the Royce equipment allowed the researchers to explore the possibility of in-situ field-assisted crystallisation in the growing anodic alumina while replacing acid anodising with advanced processing of Al in environmentally friendly alkaline solutions, driven by a complex digitally controlled polarisation signal. This alternative approach has shown to enable formation fully crystalline anodic oxide films incorporating the hard corundum phase at near to ambient bulk substrate temperatures, without compromising the integrity of underlying Al alloys.

Results of this collaborative research supported within a £2.6 million CoatIN project funded by the UK Engineering and Physical Sciences Research Council (EPSRC) were published in the scientific journal Acta Materialia. The study reveals key factors governing field assisted phase transitions in anodic alumina and their dependencies on processing parameters thus enabling optimum control of coating microstructures for specific application requirements.

FUTURE IMPACT

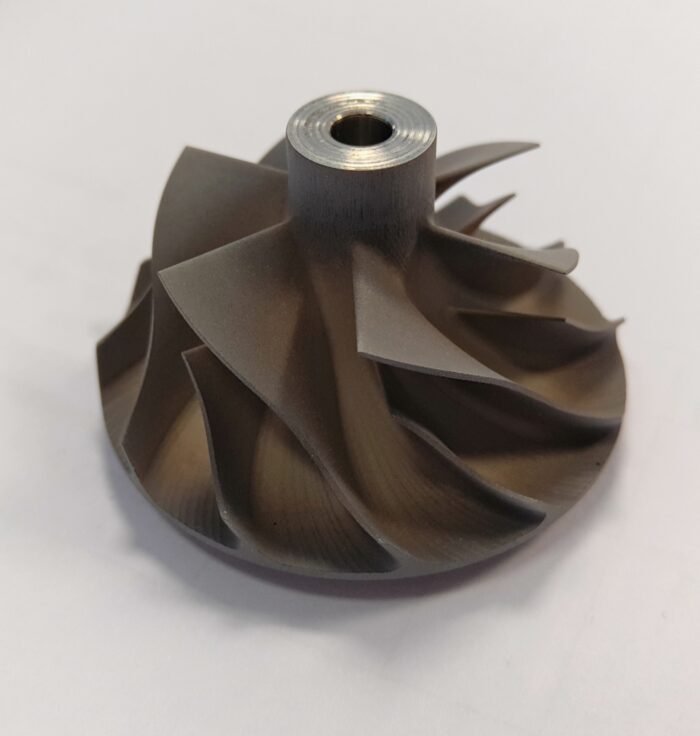

The films made possible as a result of this research are harder than hard anodised coatings and have better adhesion to AI substrates than thermally sprayed ceramic coatings. Replacing hardened steel and ceramic components operating under harsh sliding wear and atmospheric corrosion with the coated AI components achieved by this research will deliver lightweight and sustainable improvements to materials currently used in sectors such as aerospace and transport.

Collaborators

Download the Case Study

Applications

Coated Piston, supplied by Cambridge Nanolitic

Coated Turbocharger, supplied by Cambridge Nanolitic