This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

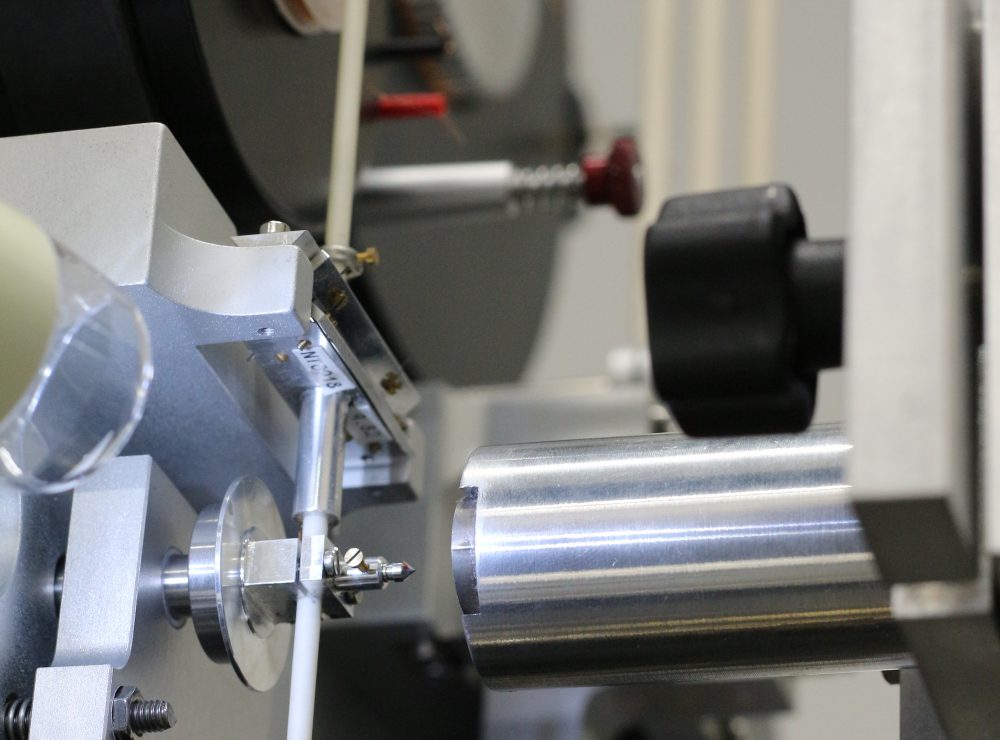

The NanoTest Vantage combines multiple nanomechanical and nanotribological test techniques over multiple force scales and temperatures.

- Partner:The University of Sheffield

- Facility:Royce Discovery Centre

- Availability:Available

Or call us now on 0161 275 8382

Detailed Description

The NanoTest Vantage has a high degree of functionality and can be used to study a wide range of materials for both research and industrial applications.

The test techniques available include indentation, scratch, wear, friction and impact.

Two load modules are available, a low load module with a load range of 10µN to 500mN and a high load module with a range 300mN to 30N.

The NanoTest Vantage is ideally suited for testing materials at elevated temperatures up to 500°C due to its unique design.

The stage configuration allows large samples to be accommodated with a maximum testable sample area of 100mm x 50mm and a maximum sample thickness of 150mm.

The post-experiment analysis software has a wide range of capabilities including creating hardness and modulus maps in both 2D and 3D and producing stress – strain curves from experimental data.

Uses/Applications

The NanoTest Vantage can be used to study a wide range of materials systems for both research and industrial applications including:

- Metals

- Polymers

- Ceramics

- Glass

- Composite materials

- Hard coatings

- Thin films

Features

The NanoTest Vantage has a NanoTest NTX4 system controller and a high accuracy National Instruments data acquisition system with NI-MCal calibration technology.

Platform 4 software allows for instrument control, experiment design and data analysis.

Up to 100 experiments can be defined and queued to run automatically.

Maximum sample size: 100mm x 50mm x 150mm.

Temperature range: Up to 500°C.

Indentation: Load range available 10uN to 500mN with low load head, 300mN to 30N with high low head.

Scratch module: Maximum friction force 250mN, Maximum scratch distance 10mm, Scratch speed 100nm/s to 0.1mm/s.

Impact module: Acceleration distance up to 20µm, Strain rate at contact up to 104 s-1