This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

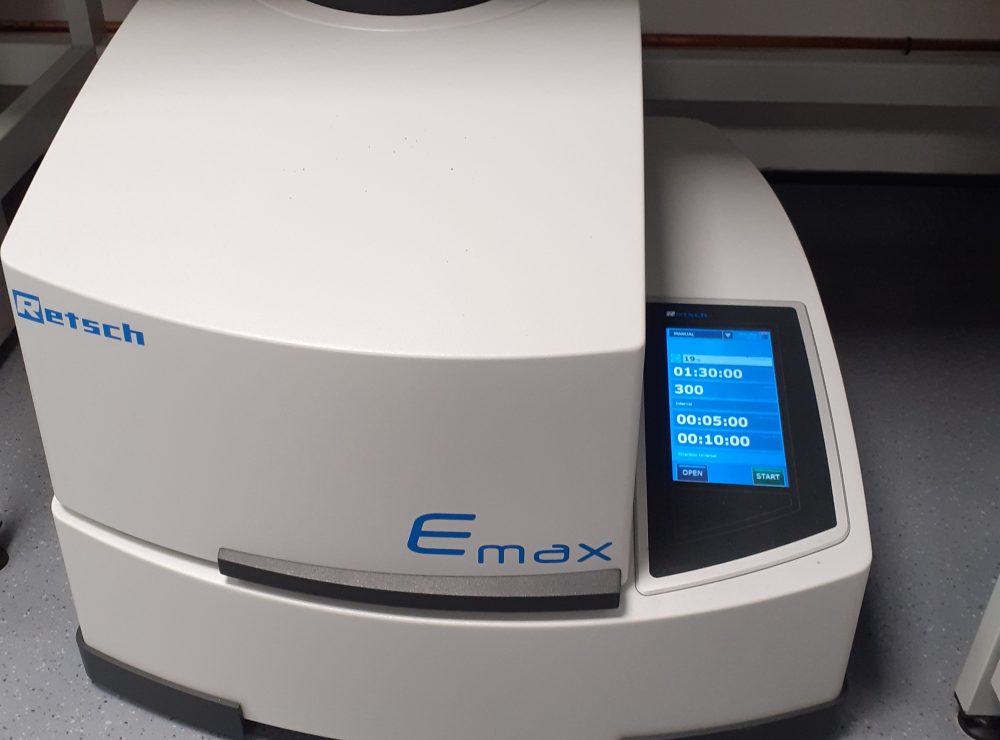

High energy ball milling apparatus for materials synthesis or preparation including solid state reactions in powder samples.

- Partner:University of Oxford

- Facility:Oxford Energy Storage Centre (OESC)

- Availability:Available

Or call us now on 0161 275 8382

Detailed Description

Planetary Ball Mills are used wherever the highest degree of fineness is required. In addition to well-proven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloying. The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times. The PM 100 is a convenient benchtop model with 1 grinding station. Operates with 2 sets of grinding jars and aeration lids and zirconia grinding balls.

Uses/Applications

Grinding of a wide variety of materials to the sub-micron scale, including: alloys, bones, carbon fibres, catalysts, cellulose, cement clinker, ceramics, chemical products, clay minerals, coal, coke, concrete, fibres, glass, gypsum, iron ore, kaolin, limestone, metal oxides, minerals, ores, paper, pigments, plant materials, polymers, quartz, semi-precious stones, sewage sludge, slag, soils, tea, tobacco, waste samples.

Application: pulverizing, mixing, homogenizing, colloidal milling, mechanical alloying

Feed material: soft, hard, brittle, fibrous – dry or wet

Size reduction principle: impact, friction

Material feed size: <10 mm

Final fineness: <1 µm, for colloidal grinding < 0.1 µm

Batch size / feed quantity: max. 1 x 220 ml, max. 2 x 20 ml with stacked grinding jars

No. of grinding stations: 1

Speed ratio: 1 : -2

Sun wheel speed: 100 – 650 min-1

Effective sun wheel diameter: 141 mm

G-force: 33.3 g

Material of grinding tools: hardened steel, stainless steel, tungsten carbide, agate, sintered aluminium oxide, silicon nitride, zirconium oxide

Grinding jar sizes: 12 ml / 25 ml / 50 ml / 80 ml / 125 ml / 250 ml / 500 ml

Interval / Pause time: 00:00:01 to 99:59:59