Through the Centre of Expertise in Advanced Materials and Sustainability (CEAMS), Cellerate collaborated with The University of Manchester and the Henry Royce Institute (Royce) to conduct cutting-edge research into advanced laser processing techniques aimed at enhancing the quality control and precision of their automated battery manufacturing systems.

Lithium-ion batteries (LIBs) remain a dominant electrical energy storage technology powering sectors from consumer electronics and electric vehicles to stationary energy storage and industrial-scale systems.

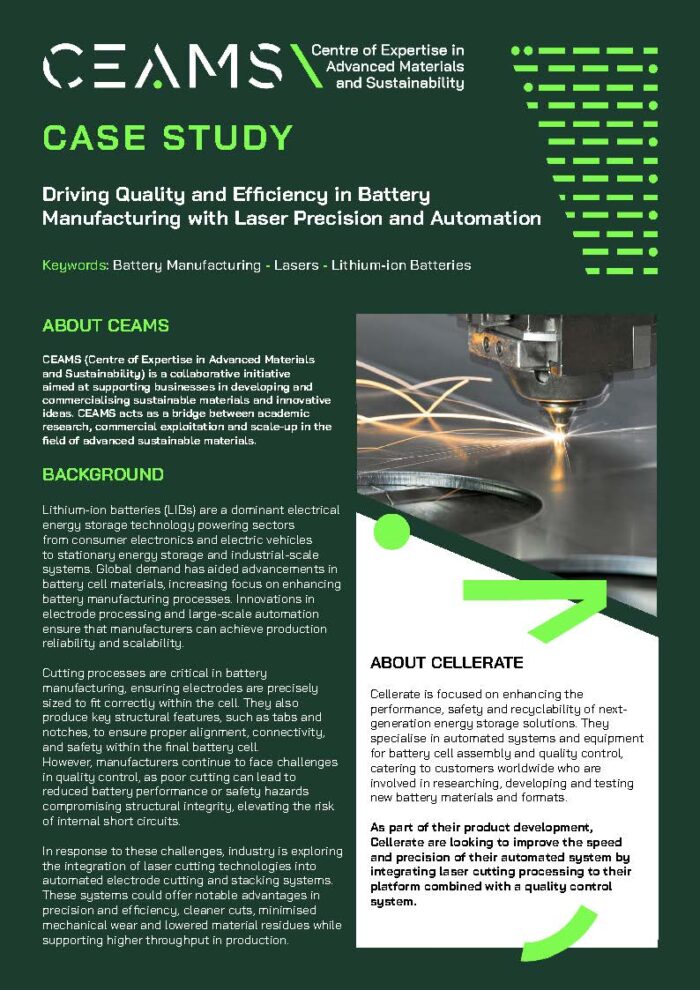

Within battery manufacturing, cutting processes play a critical role by ensuring electrodes are accurately sized to fit correctly within the cell.

However, manufacturers continue to face challenges in quality control, as poor cutting can lead to reduced battery performance or safety hazards compromising structural integrity, elevating the risk of internal short circuits.

In response to these challenges, industry is increasingly exploring integrating laser cutting technologies into automated electrode cutting and stacking systems. These systems could offer notable advantages in precision and efficiency, cleaner cuts, minimised mechanical wear and lowered material residues while supporting higher throughput in production.

As part of their product development, Cellerate are looking to improve the speed and precision of their automated system by integrating laser cutting processing to their platform combined with a quality control system. By collaborating with Royce and the University of Manchester’s Laser Processing Research Lab, Cellerate received expert guidance in selecting and optimising the key laser system parameters most likely to impact cut quality on across a range of electrode and separator materials provided by the company.

By providing avenues to access state-of-the-art laser technologies and deep technical expertise, CEAMS is positioning itself at the forefront of developing transformative manufacturing methods that support the advancement of sustainable battery technologies.

—

The Centre of Expertise in Advanced Materials and Sustainability (CEAMS) is funded as part of the Department for Science, Innovation and Technology’s (DSIT) Innovation Accelerator programme. It will build on existing capability anchoring strategic businesses to the area.

Initially funded as a two-year pilot, CEAMS is led by a consortium of expert partners, including: Rochdale Development Agency (RDA), Henry Royce Institute, National Physical Laboratory (NPL), High Value Manufacturing Catapult (HVM Catapult) and its centres: Centre for Process Innovation (CPI), National Composites Centre (NCC), Advanced Manufacturing Research Centre (AMRC) and Manufacturing Technology Centre (MTC).

In March 2025, CEAMS secured further funding as part of the Innovation Accelerator programme’s one year extension, enabling the programme to continue to drive sustainable materials innovation.

To learn more about CEAMS, click here