Royce facilities at the University of Leeds are hosted at the Bragg Centre for Materials Research within the Sir William Henry Bragg Building, a £96m development to create an integrated campus for Engineering and Physical Sciences to build on a shared interaction between these disciplines.

Located on the north-east quarter of the University campus, the 15,700m2 building enables the integration of the University disciplines of Engineering, Physics and Astronomy and Computing along with the provision of critical central teaching and social interaction spaces.

The Bragg Center for Materials Research brings together scientists and engineers across a wide range of disciplines to work on six research themes, pursuing both fundamental and applied research.

The Bragg Centre works with industry and other partners to develop new insights and solutions for innovative products, devices and applications. It also provides world-leading experimental and analytical facilities to understand and build materials from the atomic to the macro-scale.

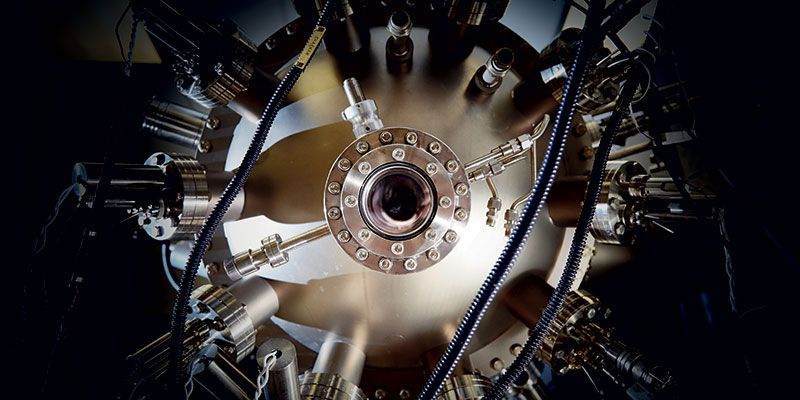

Core Facilities

The Bragg Centre brings together advanced facilities for growth, fabrication, analysis and characterisation of materials. Our facilities are supported by our theoretical and modelling expertise.

Growth

Fabrication

Analysis

Modelling and Simulation

Technology Platforms

Royce Technology Platforms, which sit within our Research Framework, are groupings of cutting-edge facilities and expertise.