Overview

Mission: To enable chemical, microstructural and mechanical property characterisation of highly active materials to further a mechanistic understanding of actinide chemistry and radiation effects on materials and underpin a safe and efficient nuclear power industry.

Capability: The Irradiated Materials, Fuels and Actinides Handling and Characterisation platform is an open-access facility for academic and industry collaborators via Royce or National Nuclear User Facility (NNUF) access schemes. Hosted at the National Nuclear Laboratory’s site at Sellafield, it consists of mainly high-activity shielded facilities at the Active Handling Facility (AHF) operating in conjunction with the high alpha and medium active laboratory facilities of Central Laboratory.

Multiple capabilities located within a heavily shielded high active cell at the Active Handling Facility (AHF), enable post-irradiation characterisation of α, β and γ highly active nuclear material using remote handling techniques. Royce funded equipment together with NNL supporting equipment provide the capability to size reduce, prepare and characterise irradiated material using optical microscopy, SEM (with EDX, WDX and EBSD), Raman Spectroscopy and small-scale mechanical testing.

High integrity alpha active gloveboxes and fumehoods are available in NNL’s Central Laboratory to analyse medium to high alpha active materials (U, Np, Pu, Am) in both solid and solution state to enable reaction monitoring, speciation and phase characterisation. Central Laboratory also hosts the Electron Optics capability that allows the characterisation of irradiated fuels and structural materials, wasteforms and other materials at length scales from the millmetre to Ångstrom. Working with industry, government and academia, we have experience of analysing materials from a variety of reactor sources, simulated and test irradiation programmes and from industrial plant using state-of-the-art preparation techniques and a range of analytical techniques. These include X-ray microtomography, SEM, FIB , plasma FIB with SIMS and (S)TEM equipped with EDX and EELS analysis systems to provide structural and compositional information on volume reduced pieces of high activity materials, from AHF, to provide an integrated offering to high activity materials analysis.

NNL has access to a large variety of material from historic waste forms to irradiated spent fuels, cladding, graphite and actinide compounds, which are available to access on request allowing a user the unique opportunity to gather a range of material property information on high active spent nuclear fuel and material.

Capability

Micro-Raman Spectroscopy

A brand new, state of the art, micro-Raman spectrometer is available for use at NNL’s Central Laboratory. The instrument is capable of analysing a wide variety of radioactive materials and liquids either in an alpha active glovebox or fumehood environment.

The glovebox is fitted with fibre optic feedthroughs to allow analysis with 514 or 785nm Compact Fibre Optic Probes (CFOPs) and can analyse high specific activity alpha materials such as AmO2, PuO2 and MOx.

The fumehood has 514, 633 and 785nm lasers with a motorized x,y,z stage and LiveTrack dynamic focusing.

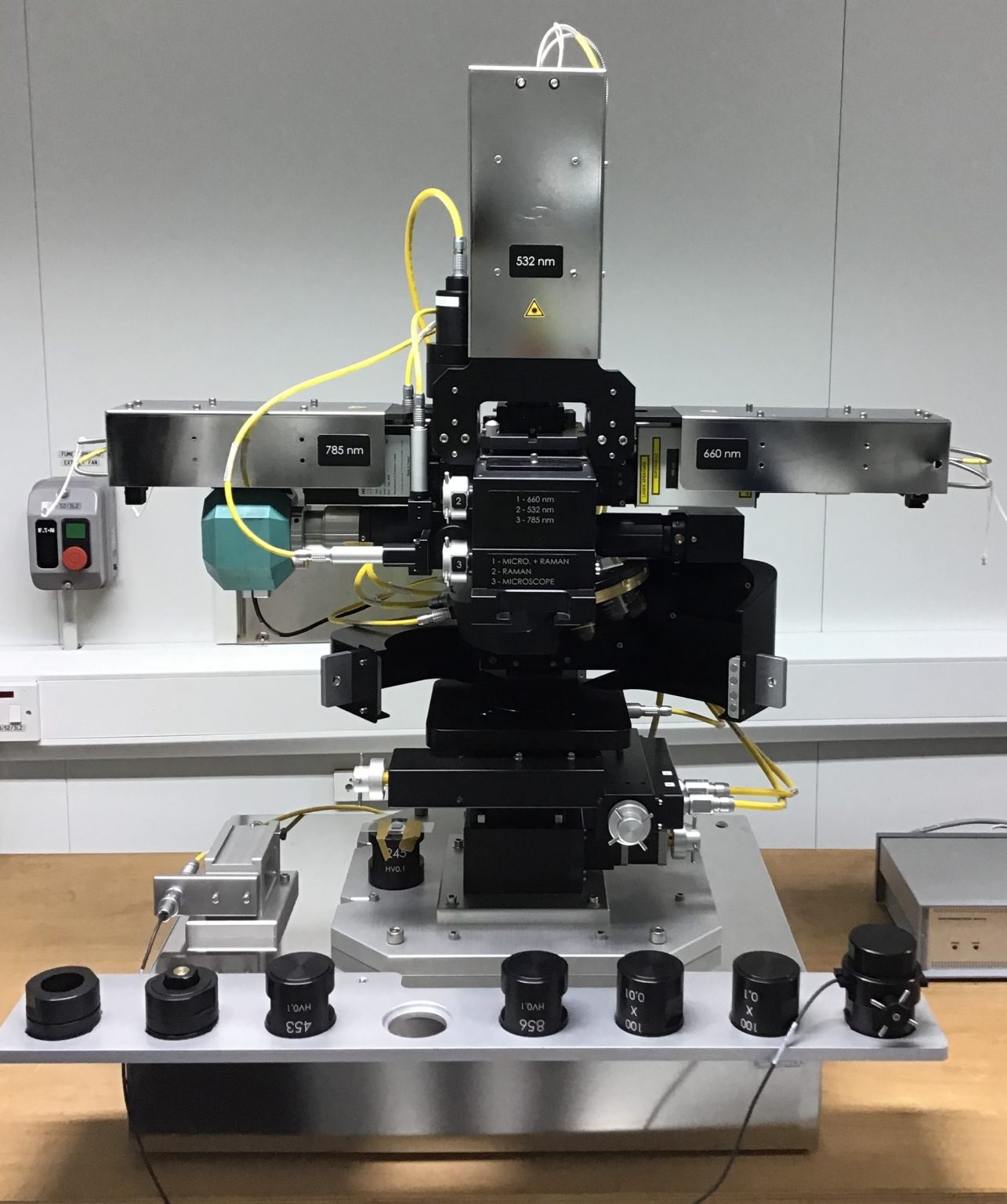

Hot Cell Optical Microscope with Triple Raman Spectroscopy and Microhardness Tester

A nuclearized Olympus optical microscope with three Raman lasers and a microhardness HV tester (Vickers), is currently available for use in the non-radioactive setting of the NNL Workington Facility. It will be installed in the Active Handling Facility at The NNL Active Handling Facility.

The multiple capabilities of this microscope allow complete characterisation of highly radioactive samples, including but not limited to, irradiated fuels, cladding, graphite and waste forms, available in the Active Handling Facility, at request. The optical microscope is complemented by the three Raman lasers allowing features of interest to be visually identified, together with the chemical composition determined. Further mechanical property information can be inferred by the microhardness tester.

Irradiated Materials Characterisation

Plasma Focused Ion Beam (PFIB)

The Tescan XEIA PFIB is a national asset for the characterisation and preparation of active material samples in the UK. Compared to a Ga+ ion FIB, the PFIB is considerably faster (up to x 50) allowing for higher volume samples to be milled and analysed than previously possible.

The PFIB is fitted with a TOF SIMS system, capable of operating in negative/position modes – allowing for the detection of a wide variety of isotopes – including those of hydrogen. This is a first for any active FIB in the UK.

Detailed X-ray mapping and analysis is possible due the FEG electron source and two large detectors; a Bruker 60 mm2 (1 Sr) FlatQuad optimised for maximum X-ray collection and Bruker 100 mm2 main detector which allows greater flexibility with other imaging modes. Additionally, electron backscatter diffraction capability allows grain orientation mapping using a Bruker EBSD (with TKD) detector.

By combining the above techniques with the milling aspect of the PFIB allows for unprecedented site-specific analysis and sample preparation. The acquisition of 3D datasets is greatly enhanced by the rapid milling capability. Examples of use could include: preparation of TEM lamella for radiation induced segregation analysis at grain boundaries, mapping of grains using EBSD, preparation of APT needles characterisation of zirconium oxides using SEM and many more.

200 kV Aberration-Corrected FEG-TEM - JEOL Arm-200CF with EDS and EELS

A 200 kV aberration-corrected FEG-TEM with EELS capability is expected to be available for use at NNL’s Central Laboratory.

Installed in the active area of Central Laboratory on Sellafield site, the instrument is capable of sub-Angstrom imaging resolution, and atomic resolution chemical analysis by EDS (0.98 Sr Oxford Instruments X-Max 100 TLE detector), and Gatan GIF Quantum 965 ER with Dual EELS and EFTEM capabilities.

The instrument is further supported by NNL’s FIB and PFIB instruments, as well as ion mill and electropolishing equipment for TEM sample preparation.