Overview

Alloy development is where traditional industries and researchers alike look to new materials to meet the challenges posed in the transition to zero carbon, sustainable manufacture, and fostering a circular economy.

Over two purpose-built sites our dynamic team supports all stages of discovery and prototyping from:

- Production, through to

- Processing,

- Testing, and

- Characterisation.

Our facilities have been successfully used in the production of most engineering alloys and development materials, including steels, high temperature super alloys and refractory metal alloys, as well as high purity Ti powder and other powders.

Previously inaccessible methodologies for accelerated alloy development are unlocked through close synergy with the Near-Net Shape Manufacturing platform. Manufacturing routes can be optimised through collaboration with the Thermomechanical Processing platform, and novel sustainability and recycling protocols are explored by considering a holistic approach to cross-industry alloy development.

Capability

Royce at the University of Sheffield combines computational material design, high-throughput materials discovery, rapid scale-up, and material property screening, to deliver a step-change in the manner novel materials are developed for specific applications.

Our capabilities support the key technical challenge of innovating processes to efficiently fabricate and test material libraries, whilst simultaneously capturing sufficient information which can be shared with manufacturers to enable rapid deployment to occur.

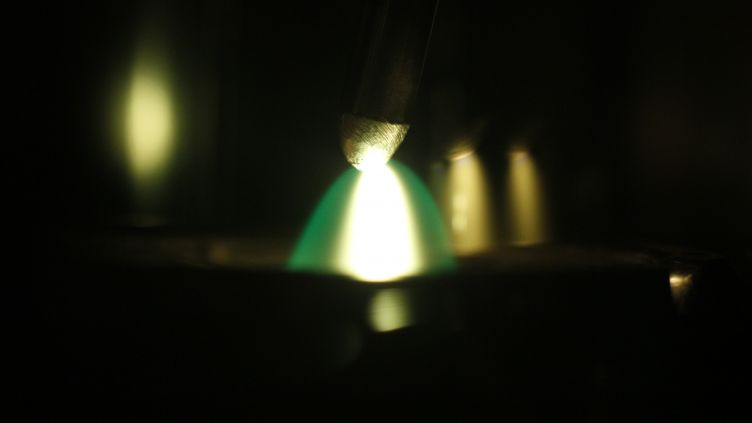

Arc Melting

Arcast Arc 200 - Arc Melter

The arc melting furnace can melt metals and alloys at over 3000°C with the aid of the electric arc between the non-consumable tungsten electrode and the copper crucible. Therefore, it is a very useful device for the rapid production of Ti, Zr, Fe, Co, Ni-based alloys and also the high entropy alloys (HEA) containing refractory metals. It is capable of melting non-reactive and reactive metals up to 200g.

The furnace is equipped with a diffusion pump that shortens the time required for reaching high vacuum levels. The electromagnetic stirring function that is applied during the melting is very effective for obtaining homogenous alloys. The furnace also has a manipulator for flipping the samples without breaking the vacuum. Liquid metal can either be solidified inside the crucible or tilt casted into the copper mould that is attached to the copper crucible

Vaccum Induction Melting

Consarc Vacuum Induction Melter Suite

Consarc – 25kg VIM with ISM

The VIM system is a perfect tool for small-scale Fe, Co, Ni, Cu, Al-based alloy production. The furnace is also able to produce the alloys of some reactive metals such as Ti and Zr in a water-cooled copper crucible using the ISM coil.

By controlling the chamber pressure and the temperature and with the help of inductive melt stirring, it is possible to obtain homogenous alloys with desired chemistry. Melting under vacuum conditions enables slag-free melting and riddance of unwanted dissolved gasses and elements.

The over melt charger allows making alloying element charging, sample taking and temperature measurement via thermocouple. The furnace also benefits from an optical pyrometer, which makes it possible to measure the temperature of the metal without contact.

Maximum mould height can be 700 mm.

Consarc – 10kg VIM

The VIM system is the perfect tool for small-scale Fe, Co, Ni, Cu and Al-based alloy production and R&D purposes. Control of chamber pressure, temperature and with the help of inductive melt stirring, it is possible to obtain homogenous alloys with desired chemistry. Melting under vacuum conditions enables slag-free melting and riddance of unwanted dissolved gasses and elements.

The VIM system has a small (for 5 kg) coil in addition to the large (for 10 kg) one, which makes it possible to produce relatively smaller samples. Over melt charger allows making alloying element charging, sample taking and temperature measurement via thermocouple. The furnace also benefits from an optical pyrometer, which makes it possible to measure the temperature of the metal without contact. It also has a rotating mould stage to cast multiple samples in one heat.

Maximum mould height can be 350 mm.

Strip Casting

Arcast SC100 Strip Caster

The Strip Caster uses induction melting in an inert atmosphere and a water-cooled, variable-speed copper wheel to quench the metal and generate the ribbon.

It is a complete system consisting of vacuum chamber, control cabinet, high vacuum dual vane rotary pump (or turbo pump option) for 9 x 10-3 mbar vacuum, and it can produce rapidly quenched ribbons 1 - 20mm wide.

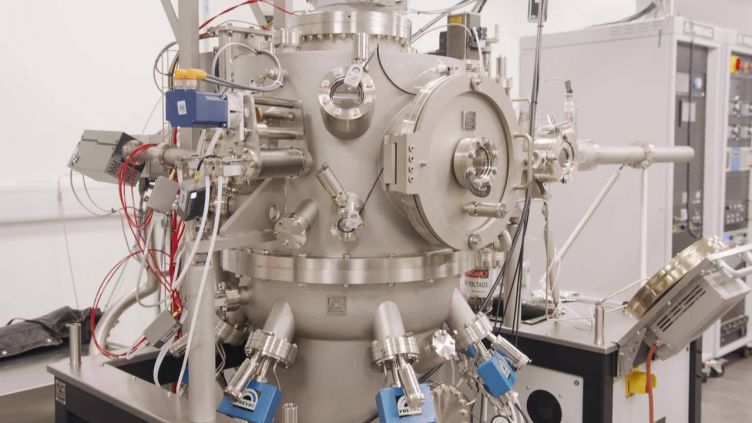

Thin Film Deposition

PREVAC Thin Film Deposition System

The system's ability to simultaneously deposit from a large number of sources, along with its capability to create variable compositions on a single wafer, makes it ideal for materials discovery in such areas as high entropy metal alloys (alloys with five or more elements in similar proportions).

The system will also allow the exploration of new functional materials systems, for example, thin-film magnetic multi-layers and functional ceramics.

Slot Die

FOM Technologies Slot Die Coater

The system is standard equipped with slot-die coating heads with additional coating and printing stations available on request. This powerful system enables its users to accelerate the development of new device structures, ink formulation, and fabrication processes by reducing the gap between small batch processes familiar in R&D such as spin coating, and continuous roll-to-roll processes necessary for large scale production

Screen Printer

Haikutech P-400S

This equipment is for high accuracy electrode, dielectric, and metallisation printing. It accepts regular screens and stencils. Substrate alignment by pins (option) to an accuracy and repeatability of 25 microns compared to the edge of the substrate size. Manual high accuracy alignment assisted by CCD cameras against hairlines on a screen. All essential functions servo motor controlled, and automatic snap-off and substrate height setting with stepper motor.