Researchers at the National Graphene Institute (NGI) have, for the first time, identified and mapped chemical groups on monolayer graphene with nanoscale resolution, using atomic-force microscopy coupled infrared spectroscopy (AFM-IR).

The powerful technique provides a non-destructive route to unambiguous identification of chemical groups and their distribution on the surface of graphene. The breakthrough is key to better understanding the type of 2D materials and their chemistry down at the nanoscale, which promises to innovate a range of applications, from electronics and sensors, to new composites, smart coatings and biomedical devices.

Dr. Aravind Vijayaraghavan of the School of Materials at The University of Manchester and corresponding author of the paper said,

“There are very few applications where we use pristine, unmodified graphene. We’re always doing some kind of chemistry on the graphene, intentionally or unintentionally. Until now, a technique has not been available where we can non-destructively map what kind of functional groups have been added on to graphene or any 2D materials with nano-scale resolution.”

Cian Bartlam, a PhD student and lead author of the paper, said,

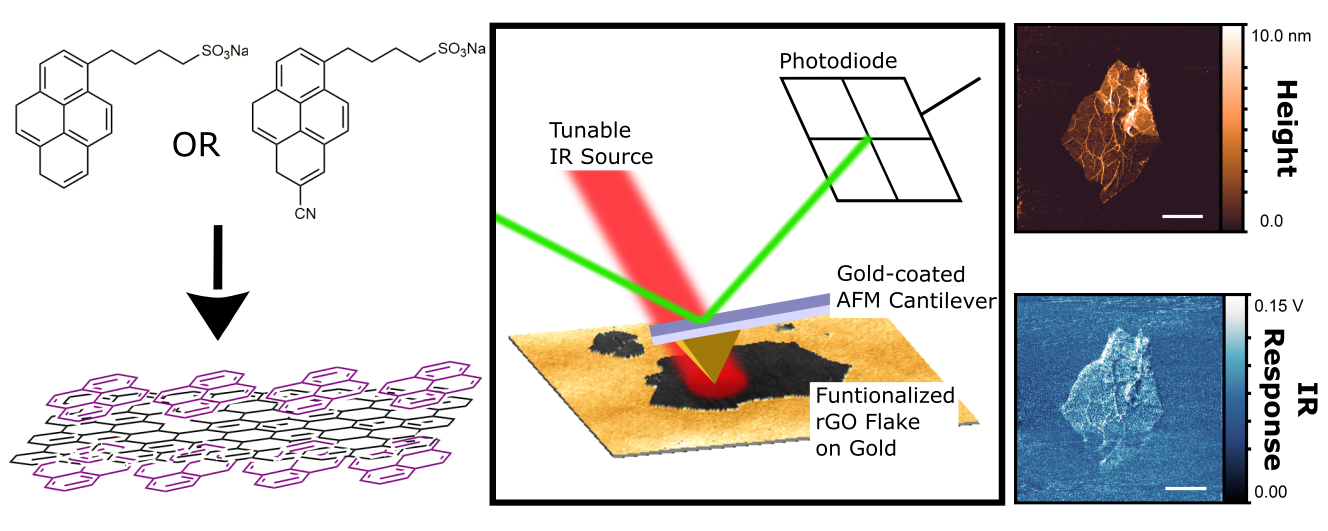

“This technique works by vibrating certain chemical groups with infrared light and measuring their thermal expansion with an extremely high-resolution probe. Normally this is very difficult, as you can imagine a molecule doesn’t expand very much, particularly on graphene which has such a high thermal conductivity and is only one atom thick. Here we’ve shown that it is possible to perform these measurements, which have great potential to solve some of the problems facing 2D material research.”

The research, to be published in Carbon, will lead to further work in the field with the Henry Royce Institute and the University of Manchester investing in new Bruker Nano IR 3s instrument to be installed at the NGI later this year.

This will allow research in this field to advance into widespread use of chemical mapping and chemical characterisation of 2D materials. When the new equipment is in place, researchers will have a greater understanding of the behaviour and interactions of graphene, reducing the time, and trial and error nature, of producing new materials systems and applications.

Schematic representation of the AFM-IR technique and the height and IR response from a monolayer functionalised graphene flake