Overview

Carbon fibre composites play a big role in the construction and transport sectors. However, it is challenging to repurpose these fibres, which often end up in landfill in large quantities. The lead organisation in this project, Sigma Lithium, develops 3D-Li anodes for next-generation batteries, aiming to deliver high-power and high-energy-density solutions that support net-zero emissions goals. Sigma Lithium uses recycled carbon fibre sheets as structural scaffolds to manufacture their anodes and has collaborated with the University of Oxford to develop a solid-state battery using a polymer-based electrolyte. This battery incorporates recycled carbon fibre, recyclable and bio-based monomers, and a 3D-Li anode produced via low-energy, dry processing under low-vacuum conditions—making the overall cell design both resource- and energy-efficient.

About the Project

Carbon fibre composites have long been used to reinforce buildings, bridges, and other structural elements, as well as in aerospace and automotive manufacturing, due to their superior physical properties compared to steel. However, they are challenging to repurpose, and carbon fibre landfill is fast becoming an environmental issue as demand for the material increases. In this project, a solid polymer electrolyte lithium (Li) metal battery was developed using recycled carbon fibre that would otherwise be sent to landfill, along with recyclable, bio-based materials.

Project details and results

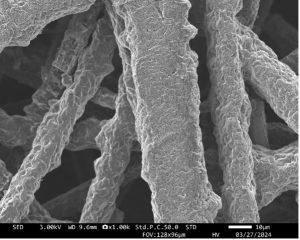

Sigma Lithium manufactures 3D-Li anodes, which provide high surface area, alleviate dendrite formation, and limit the use of excess Li. These anodes are manufactured with dry processing under low-vacuum conditions, which lowers the environmental impact compared to similar technologies. For this study, non-woven recycled carbon fibre veils were used as scaffolds for lithium deposition, enabling the production of 3D-Li anodes while reducing material waste. These porous 3D-Li anodes were then combined with polymer electrolytes developed by the University of Oxford to assemble a solid-state cell. The Oxford team synthesised novel polymers for this project using bio-based, recyclable monomers, supporting the project’s sustainability aims. Together, these materials and processes contribute to the development of high-energy-density batteries aligned with net-zero objectives and the circular economy.

Novel polymers with various chain lengths were synthesised and characterised using a range of analytical techniques including TGA, SEC, DSC, and NMR spectroscopy. These polymers were then combined with lithium salts to form polymer electrolytes and analysed using rheological methods and impedance spectroscopy to assess conductivity and processability. This work was carried out at the University of Oxford by the team led by Dr Georgina Gregory. The polymer electrolyte with the highest ionic conductivity and viscosity best suited for infiltration into the 3D-Li anode was selected for cell fabrication. At Sigma Lithium, the 3D-Li anodes made from recycled carbon fibre were exposed to dry air after production to generate a passivating layer, helping to limit reactions between lithium, environmental impurities, and electrolytes. This passivating layer was characterised using X-ray photoelectron spectroscopy (XPS) at the University of Oxford with the assistance of Dr Robert House.

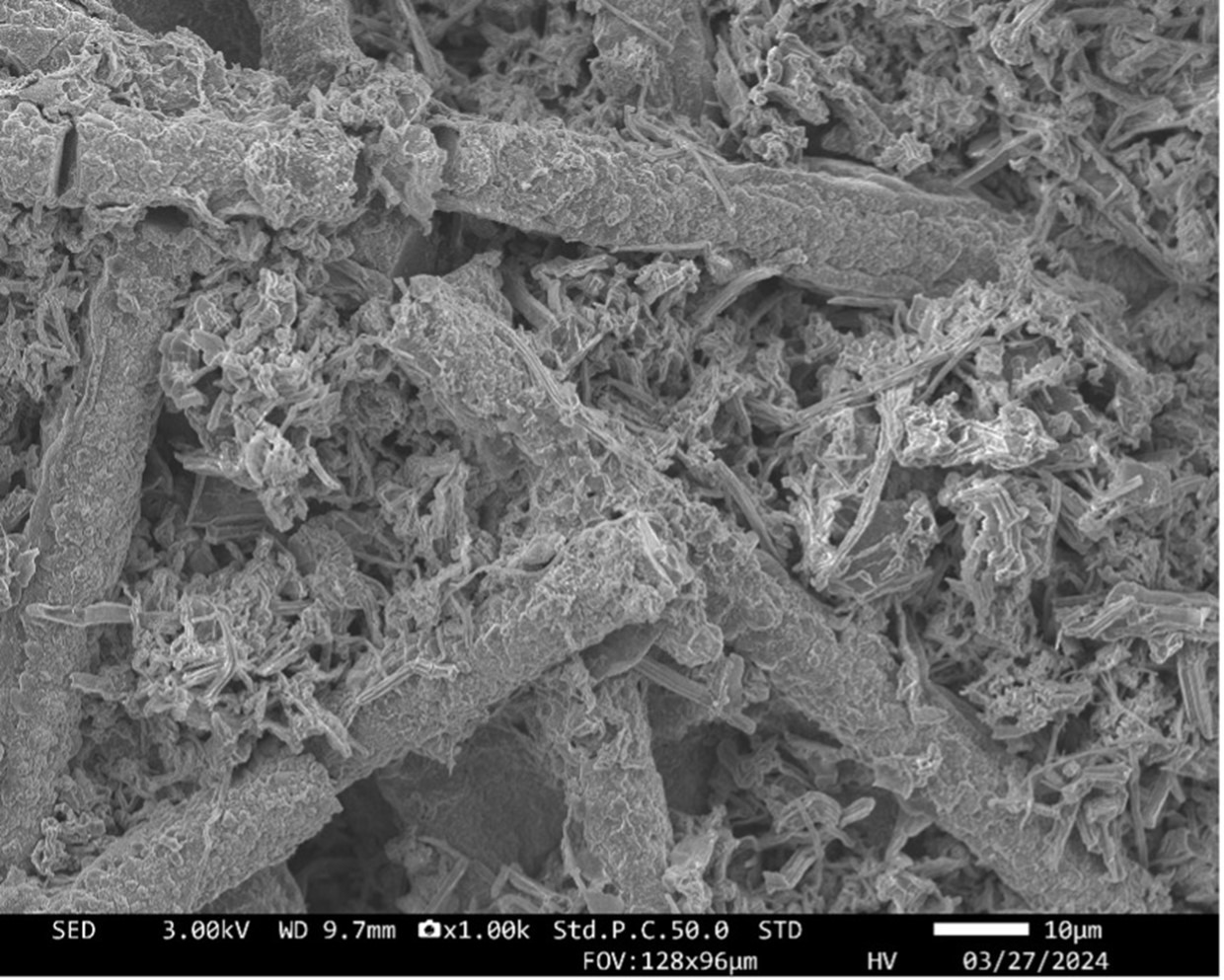

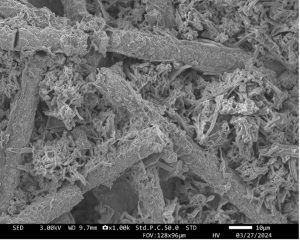

Coin cells were assembled using both flat lithium and 3D-Li anodes, paired with the selected polymer electrolyte. These cells were cycled at various current densities and capacities at Sigma Lithium. To further investigate the interaction between lithium metal and the polymer electrolyte, three-electrode PAT cells were constructed at the University of Oxford, and scanning electron microscopy (SEM) was used to study morphological changes at the anode surface. Both anode configurations demonstrated successful cycling, although further optimisation of the polymer electrolyte chemistry is required to improve its stability against lithium, and more work is needed to enhance infiltration and utilisation of the 3D structure.

Picture 1: 3D-Li before polymer electrolyte and cycling

Picture 2: 3D-Li electrode after cycling with the polymer electrolyte

The project was driven by the requirements of the aerospace and automotive industries for safer, high-capacity batteries capable of delivering high power without compromising performance. Sigma Lithium is now in discussion with potential end users interested in joining the collaboration and contributing practical insights. The use of recycled carbon fibre in the 3D-Li anodes is particularly significant in the development of more sustainable battery technologies. Sigma Lithium is planning future collaborations with specialists in recycled carbon materials and their application in industrial contexts.

This project represents a promising foundation for advancing solid polymer batteries based on 3D-Li architecture-offering high performance while addressing growing demand for environmentally responsible energy storage solutions.

Collaborators

The lead organisation in this project, Sigma Lithium, uses recycled carbon fibre sheets as structural scaffolds to manufacture their anodes and has collaborated with the University of Oxford to develop a solid-state battery using a polymer-based electrolyte. This battery incorporates recycled carbon fibre, recyclable and bio-based monomers, and a 3D-Li anode produced via low-energy, dry processing under low-vacuum conditions—making the overall cell design both resource- and energy-efficient.

"We are very excited about the project and view it as an important starting point for developing solid polymer batteries based on 3DLi architecture, delivering high performance while meeting the growing demand for sustainable energy storage solutions."

Gleb Ivanov, CEO

Sigma Lithium