Description

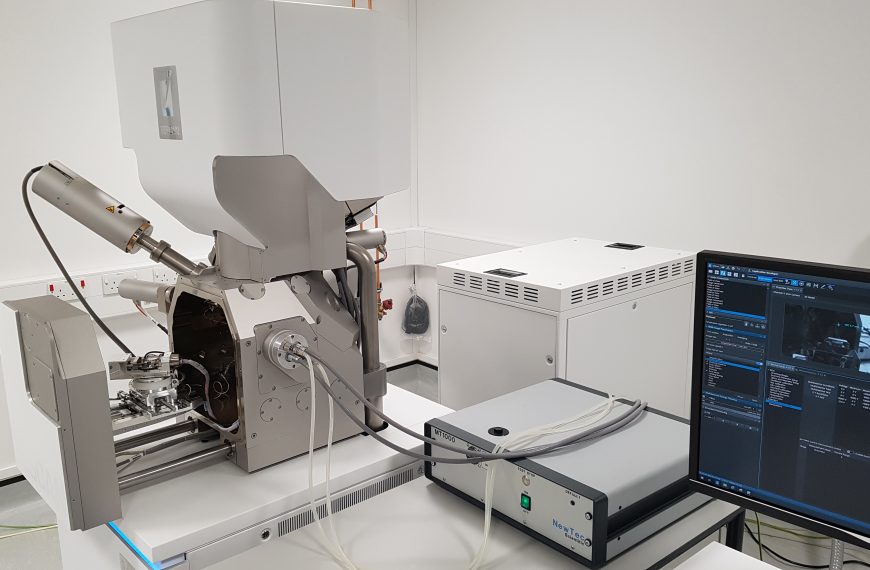

The TANIST (Tescan And Newtec In-Situ Testing) Station is the first stage in a project to develop a custom-built system that allows thermal and mechanical testing with simultaneous microstructural observations at an unprecedented spatial and temporal resolution. This will allow full automation with experiments to run 24/7, enabling measurements to take place between smaller load/temperature steps over a larger range than previously possible. This greater resolution will enable observation of microstructural developments with the addition of detectors to measure crystallographic orientation while testing so that a specimen’s macro/micro-mechanical response can be directly linked to local crystallography and microstructure.

Uses / Applications

“This is the first time I’ve used an in-situ test rig having control software designed with the user in mind. It is easily as capable as a full-sized bench-top mechanical test rig, only with the added advantage of having an SEM attached. Currently, the labour-intensive nature of in-situ testing is a bottleneck to collecting a high density of data. Automation of the process is intended to alleviate this. It’s exciting to be part of a development project that will help researchers and students push the boundaries of in-situ testing.”

Albert Smith –R&D Applications Engineer, Tescan UK