Description

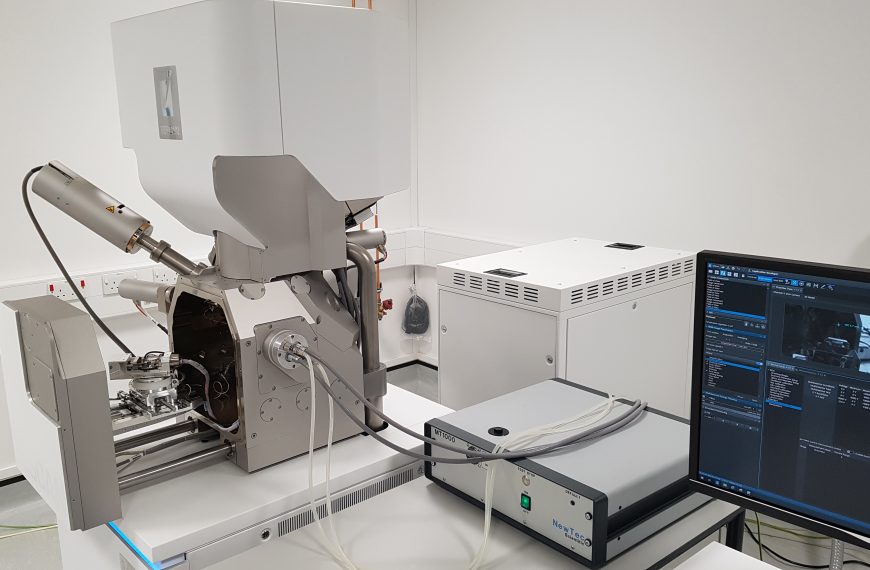

These equipment are part of the Electron Microscopy Centre of the Multidisciplinary Characterisation Facility.

Most SEM-based in situ mechanical testing techniques are designed for FIB-fabricated micron-scale specimens, which are well-suited for studying deformation mechanisms in single-crystalline materials or a limited number of crystals. While this approach simplifies the problem and provides fundamental insights into deformation mechanisms, it may also obscure critical microstructural interactions by limiting analysis to a small number of crystals.

The TANIST (Tescan And Newtec In-Situ Testing) Station is a system that allows thermal and mechanical testing with simultaneous microstructural observations at an unprecedented spatial and temporal resolution. Full automation permits experiments to run 24/7, enabling measurements to take place between smaller load/temperature steps over a larger range than previously possible. This greater resolution will enable observation of microstructural developments with the addition of detectors to measure crystallographic orientation while testing so that a specimen’s macro/micro-mechanical response can be directly linked to local crystallography and microstructure.

A key advantage of TANIST is its robust automation, made possible by seamless communication between the Newtec software, the TESCAN computer, and the Oxford Instruments system. The Newtec computer, running SoftStrain for the MT1000 stage and FurnaSEM for the FurnaSEM stage, takes control of critical SEM functions, including the microscope stage, beam parameters, in-column and in-chamber detectors, and Oxford EBSD and EDS detectors. This automation enables:

- Automated focus and astigmatism correction after each temperature or strain increment

- Real-time tracking of the region of interest (ROI), keeping it centered in the field of view throughout heating or loading experiments

- Automated insertion and retraction of detectors, depending on the requirements of each experimental stage

By significantly reducing the need for continuous operator presence, TANIST minimizes human error while enhancing the precision and efficiency of high-throughput in-situ SEM experiments.

Uses / Applications

“This is the first time I’ve used an in-situ test rig having control software designed with the user in mind. It is easily as capable as a full-sized bench-top mechanical test rig, only with the added advantage of having an SEM attached. Currently, the labour-intensive nature of in-situ testing is a bottleneck to collecting a high density of data. Automation of the process is intended to alleviate this. It’s exciting to be part of a development project that will help researchers and students push the boundaries of in-situ testing.”

Albert Smith –R&D Applications Engineer, Tescan UK

MT1000 - In Situ thermo-mechanical stage

- Mechanical Loading

Max. Load 10,000N

Max. Loading Rate 20 N/s

Loading configurations Tensile, compression, bending

Max. Temp. 1000°C - Heating / Cooling

Max. Temp. 1000°C

Max. Heating Rate 2°C/s

Heating Modes Homogeneous, differential

Min. Temp. -150°C

Other

Gas Injection Yes

Detector Compatibility EBSD, EDS, BSE, ETD

MT1000 - In Situ thermo-mechanical stage Mechanical Loading Max. Load 10,000N Max. Loading Rate 20 N/s Loading configurations Tensile, compression, bending Max. Temp. 1000°C Heating / Cooling Max. Temp. 1000°C Max. Heating Rate 2°C/s Heating Modes Homogeneous, differential Min. Temp. -150°C Other Gas Injection Yes Detector Compatibility EBSD, EDS, BSE, ETD FurnaSEM - In Situ thermal stage

- Heating

Max. Temp. 1200°C

Max. Heating Rate 1°C/s - Heating

Gas Injection Yes

Detector Compatability EBSD, EDS, BSE, ETD