Description

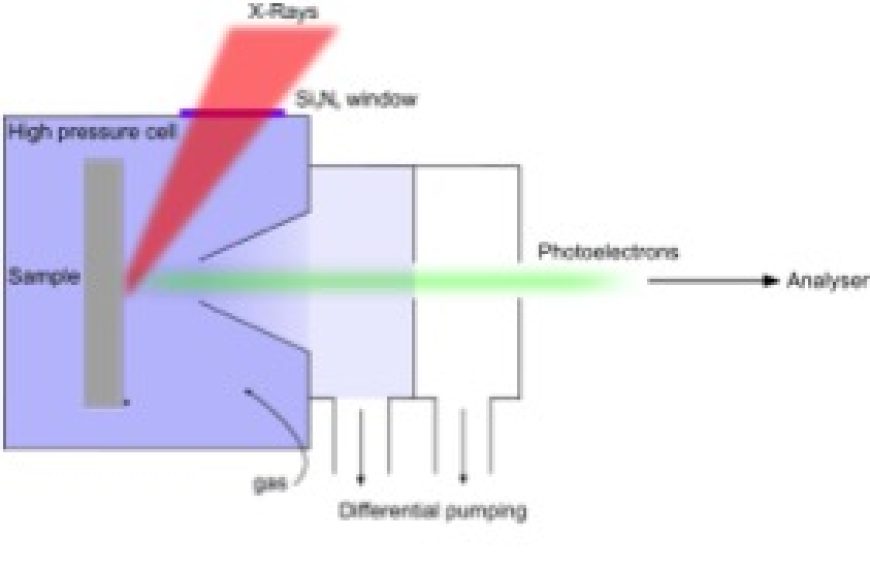

XPS is a spectroscopic technique which allows for the chemical composition of the surface of a sample to be determined. Soft X-rays are fired at the sample and photoelectrons are ejected. These photoelectrons carry information about the elements present in the sample and their chemical environment. XPS is normally a high-vacuum technique, and so restricted to post-mortem measurements. NAP-XPS is an evolution of this technique which allows the analysis of the sample in a reactive environment. This enables in-situ or operando measurements of functional materials.

Uses / Applications

Conventional XPS is performed under high vacuum and so is a post-mortem technique. NAP-XPS overcomes this limitation by placing the sample inside a special high pressure cell connected to the analyser through several layers of differential pumping. This means that surfaces can be studied in-situ during chemical reactions. Example applications include: operando characterisation of heterogenous catalysis, accelerated ageing/degredation tests of materials or operando electrochemistry of battery materials or electrocatalysts (under development).

Specification

In the NAP cell: Analysis of samples in the presence of a gas (or mixture of gases) up to a total pressure of 25 mbar. Currently available gases: CO2, H2O, O2, H2, CO, NH3. Other gases may be possible by request. Heating/cooling of samples from ~ 0ºC to 700ºC during analysis at near-ambient Pressures. In UHV: Standard UHV sample prep (sputter/anneal cycles). Cluster-ion sputtering (depth profiling of fragile samples such as polymers). Dedicated chamber for evaporation of organics etc. LEED (low-energy electron diffraction). In-situ characterisation of the solid/liquid interface is under development.