Description

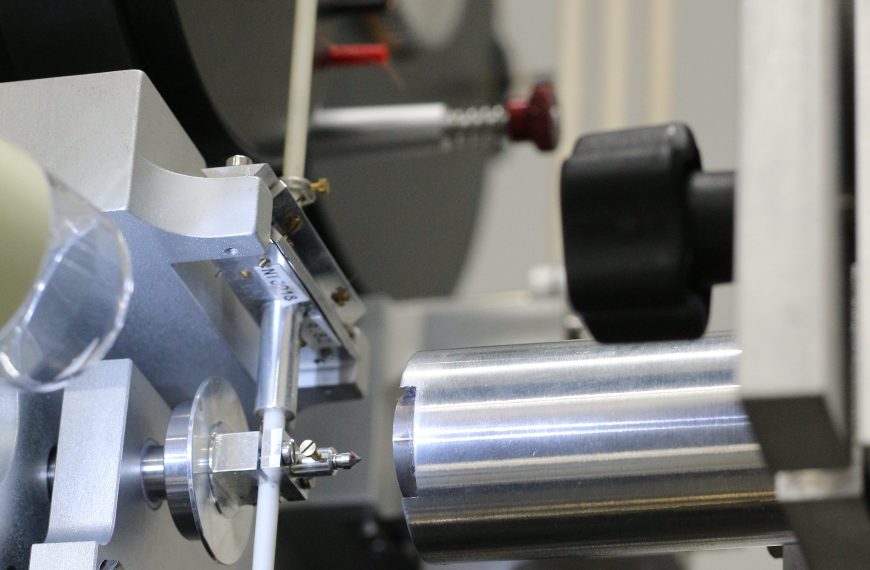

The NanoTest Vantage offers a versatile suite of nano mechanical and nanotribological testing techniques, adaptable across various force scales and temperatures, making it ideal for both research and industrial applications. Its extensive testing capabilities include indentation, scratch, wear, friction, and impact, providing comprehensive analysis options. The flexible stage configuration accommodates large samples, enhancing versatility. Additionally, the system supports up to 100 automated experiments, enabling hands-free operation and efficient handling of large data sets. The intuitive post-experiment analysis software further simplifies the process, ensuring user-friendly and efficient data interpretation.

Specification

Max. sample size: 100 mm x 150 mm x 50 mm.

In-situ optics: 5x and 20x objectives

Working environment: Standard: Air at room temperature; w/ extensive modules: Heat up to 400°C; Liquid.

Measurement modes and parameters:

Indentation: Load range available 10 µN to 500 mN with low load head, 300 mN to 30 N with high load head.

Scratch module: Maximum friction force 250 mN, Maximum scratch distance 10 mm, Scratch speed 100 nm/s to 0.1 mm/s.

Impact module: Acceleration distance up to 20 μm, Strain rate at contact up to 10 kHz.