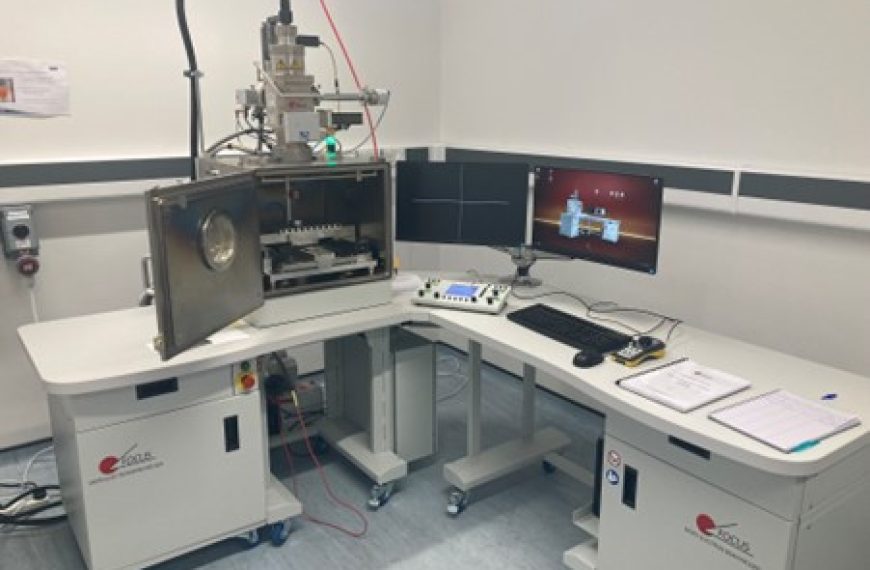

Description

It is a fine focused electron beam system, enabling EB surface treatment, welding or drilling, with up to 60 keV accelerating voltage and 2kW Electron beam welder with a 2kW electron gun, imaging and processing optics and a micro-resolution computer numeric control sample positioning system. To support the printing, joining and cladding of thin-section components activity. This system is unique to the UK as there are no capabilities currently in the low power range (0.2-2 kW).

Uses / Applications

Precision electron beam welding, surface modifications and micro drilling of small metallic components. Thermocouples can be inserted into the chamber using additional feedthrough port.

Specification

• Accelerating voltages: 5–60 kW

• Beam current: 0.015 mA – 33 mA @ 60 kV

• Max beam power: 2 kW

• Beam diameter: less than 50 µm @ 1 mA beam current. Down to 30 µm with lower current

• Chamber size: 500 x 400 x 400 mm (W x D x H)

• Workpiece dimension: 250 x 230 x 170 mm (W x D x H)

• Accuracy x/y/z stage: < 50 µm

• Travel range: +/- 75 mm (x/y), 250 mm (z only)