Description

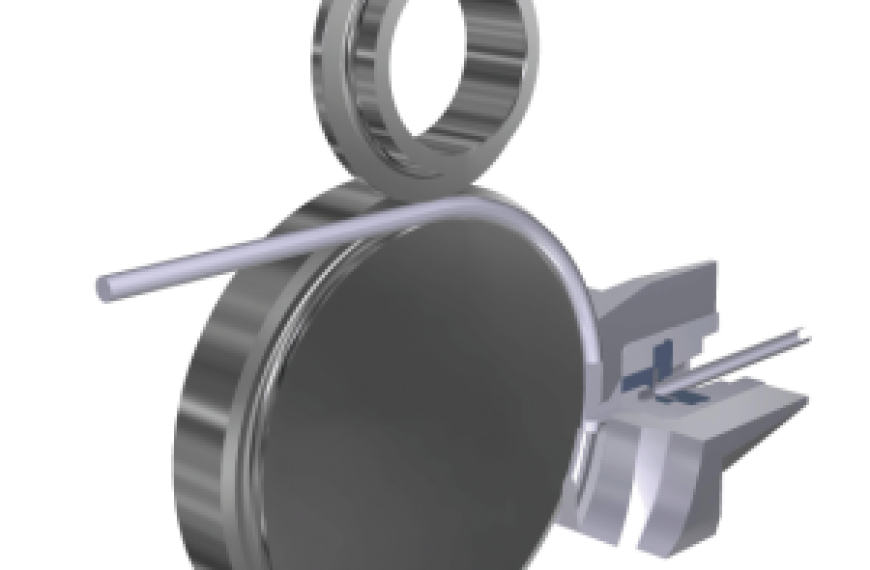

The Conform™ extrusion line is designed to extrude various metals, including copper and aluminium, through a continuous process. This method involves heating metal billets to a specified temperature and forcing them through a die to form long, uniform profiles. The system is equipped with a PLC-based control unit for monitoring temperature, pressure, and output, ensuring precise and reliable operation. Features such as induction coil heaters, a robust hydraulic system, and enhanced safety controls contribute to the machine’s efficiency and ability to handle large-scale industrial operations. The Conform™ extrusion process primarily uses non-ferrous metal feedstock such as copper and aluminium in rod form. For copper, feedstock includes electrolytic tough pitch copper rod or oxygen-free copper rod, often with diameters ranging from 8 mm to 16 mm. This metal is processed through the Conform™ machine to create continuous, extruded products like wire, busbars, and other profiles.

The process has also been expanded to work with a variety of other materials, including aluminium alloys, magnesium, zinc, and titanium; in powders, swarf and granulated form. These feedstock’s are extruded into high-density wires and strips. The feedstock can also include out-of-spec powders, such as those from additive manufacturing, that would otherwise be unsuitable for conventional processing.

Uses / Applications

The Conform™ extrusion line is widely used in industries where continuous, precise metal profiles are required. It is commonly applied in the production of electrical conductors, automotive parts, aerospace components, and structural elements. The machine’s ability to consistently produce high-quality extruded profiles makes it indispensable for sectors that demand strong, lightweight, and durable metal products.

Specification

Features

Feedstock: Bar (upto Ø10mm with existing tooling), powder, swarf and granules.

Output: Customizable profiles upto a maximum 16mm in any one direction.

Operating Temperature: Up to 900°C (1,652°F).

Cooling System: Water-cooled, equipped with heat exchangers.

Hydraulic Pressure: 10,000 psi (690 bar).

Power Supply: Induction heating system with automatic load-sensing capabilities.

Safety Features: Automatic shutdowns, emergency stop systems, and safety interlocks.

Data acquisition: Precise control and logging over extrusion processes.