Overview

The Royce non-actinide irradiated materials handling, characterisation and testing platform is located in the UKAEA Materials Research Facility (MRF), a user facility for the preparation, characterisation and testing of β/γ radioactive materials. It bridges the gap between low activity university facilities and the high activity licensed nuclear sites.

The MRF supports materials research into both structural and functional materials for the commercial realisation of primarily fusion but also new build fission power generation and particle accelerator applications.

Capability

UKAEA’s Materials Research Facility (MRF) prepares and examines samples of radioactive materials to assess their performance in nuclear reactors.

The facility at Culham Campus near Oxford is available for users working in fission, fusion and other research programmes. It is part of the UK Government’s National Nuclear User Facility and the Henry Royce Institute for Advanced Materials.

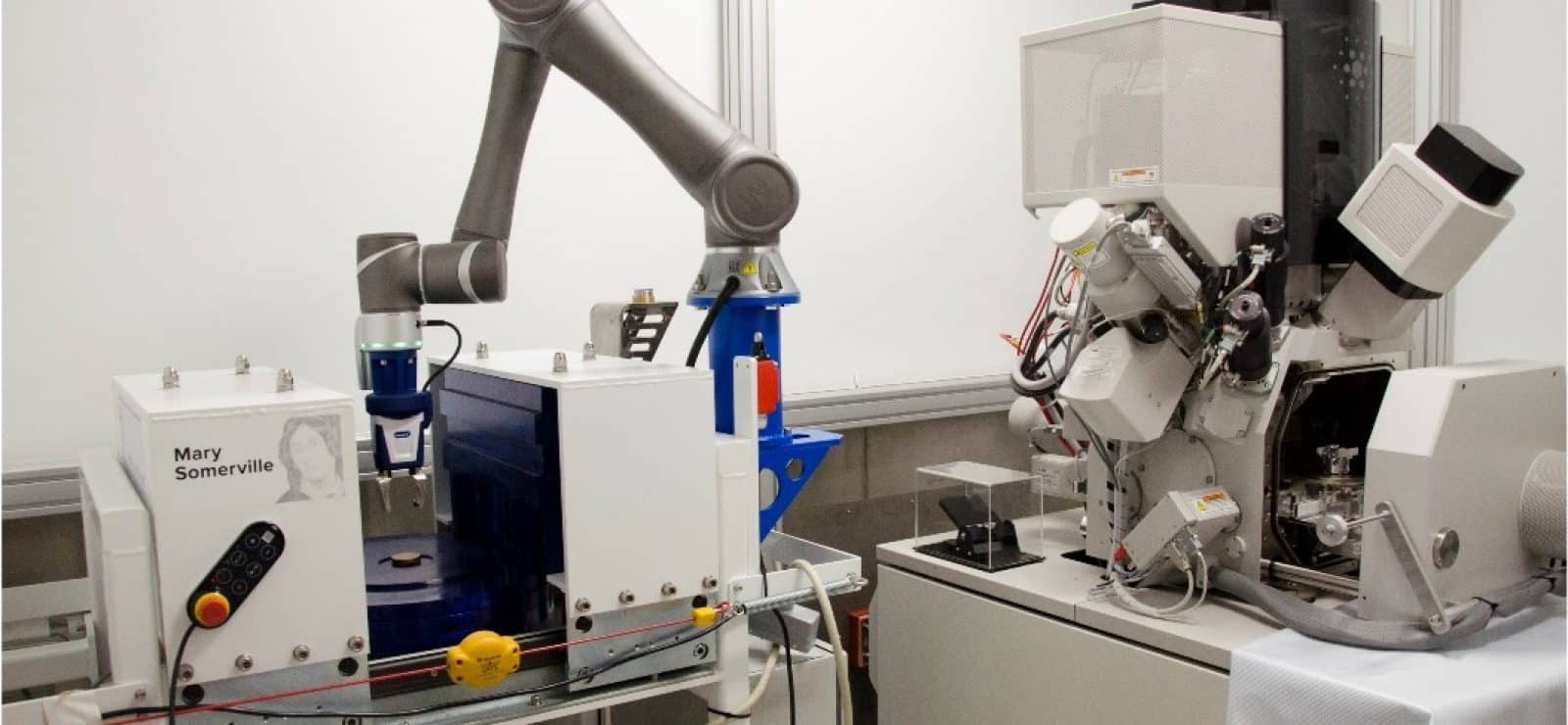

Shielded Sample Preperation

Sample cutting, grinding and polishing facilities housed in:

- High active hotcell facilities

- Low active and Beryllium glovebox

- Non-active facility

Mechanical Test Suite

- 10kN static load frame

- 15kN Fatigue load frame

- High temperature small punch test

- Instrumented indenter

- Nano position stage nano indenter

- 5kN High Vac load frame, 650°C capable with DIC

- Small scale mechanical tester with DIC

Microstructural Instrumentation

- XRD

- AFM

- RAMAN

- Gallium FIB

- SEM EDS/WDS/EBSD

Future Capability:

- Plasma FIB EDS/EBSD

- TEM

- EBSD and Cryo Ga FIB upgrades

Thermo-Physical Suite

- Dilatometer

- Simultaneous Thermal Analysis

- Laser Flash Analysis

- Impulse Excitation testing

- Pycnometry

- High Vac DSC with Mass Spec

- PPMS