This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Research Area

Nuclear Materials

Vision

The Nuclear Materials Research Area aims to:

- help increase the UK’s existing economic strengths and competitive advantages in nuclear energy, and support its net-zero ambitions, by enabling innovation in research on radioactive materials, including an experiment-with-modelling approach, via a co-ordinated network of national laboratories, nuclear user facilities, and expertise.

- develop vibrant industry- and academic-led programmes which accelerate nuclear’s

contribution to deep decarbonisation.

Above: watch Professor Francis Livens and Dr Amanda Quadling introduce the Nuclear Materials Research Area.

/

/

The UK has the largest civilian stockpile of Plutonium in the world

Introduction and Scope

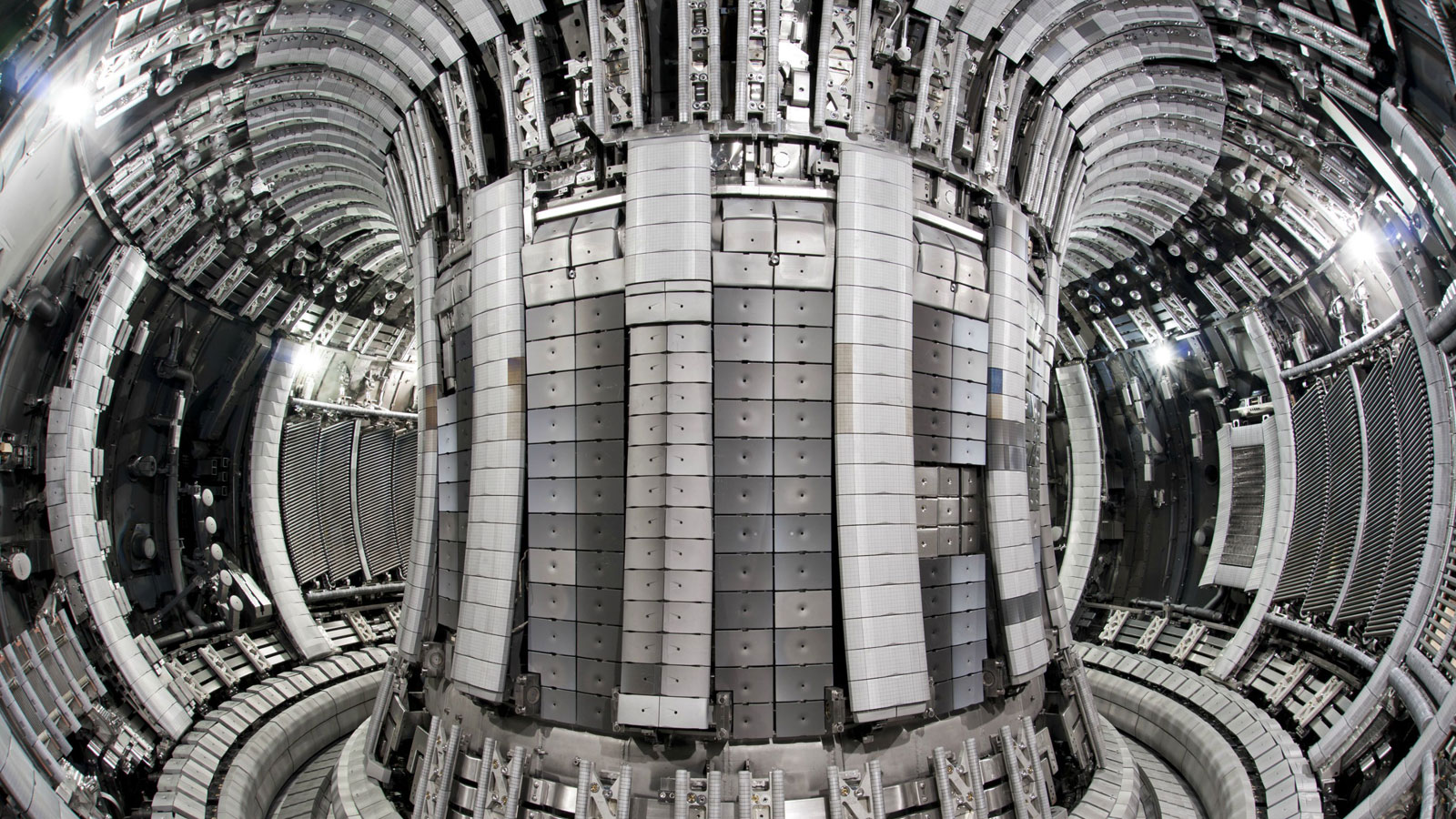

Next generation fission and fusion power stations require development of more resilient materials due to the increased demands they place on materials, from corrosion to high radiation fields and severe thermal loads.

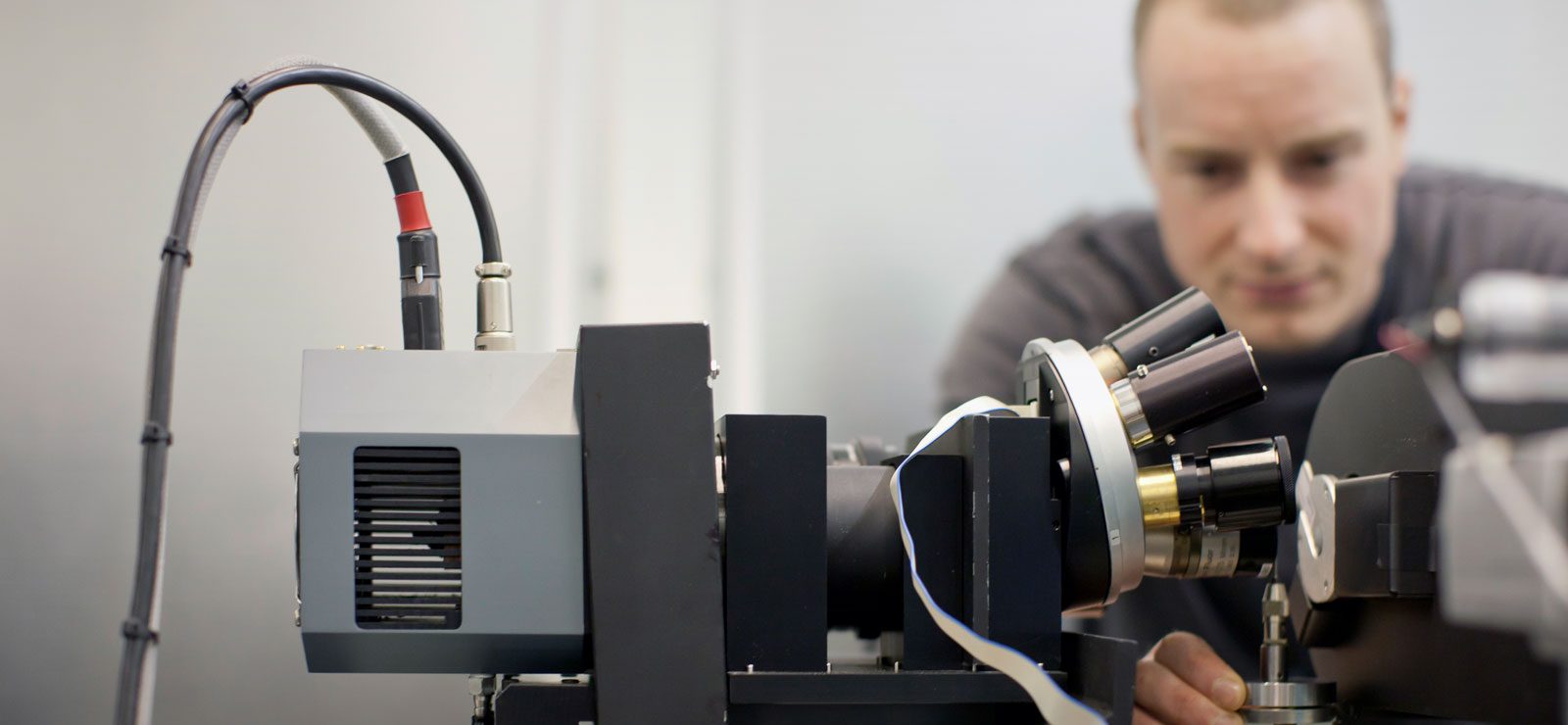

Nuclear materials will enable innovation in radioactive materials research by providing a ‘bridge in activity’ between accessible low-activity studies at academic locations and the difficult to access high-activity capability available at NNL Central Lab. Along with the National Nuclear User Facility (NNUF), we are building a national network of co-ordinated user facilities with increased applicability and functionality.

We will also seek to enhance modelling across length and time scales to aid in the development of new codes and standards, which will positively benefit new nuclear build and potentially have impact across multiple sectors.

Current and Future Research

To support development of advanced fission and fusion systems, and management of the nuclear legacy through:

- High Temperature Nuclear Systems – safety critical systems exposed to high thermal loads in AMRs (Graphite, Cladding) and Fusion designs;

- The Plutonium Lifecycle – investigating the properties of plutonium to inform future decisions on management of the largest civilian stockpile in the world, through use as MOX fuel for AMRs and/or disposal as waste;

- Materials Degradation – helping develop new codes & standards, including innovative manufacturing methods, to accelerate regulatory approval and in-service performance of new nuclear power;

- Accident Tolerant Fuels – manufacturing, characterising, and testing denser and safer fuels (U3Si2, TRISO) for deployment into LWRs, LINKS SMRs and AMRs.

Links

The strategic investment from NNUF and Royce will accelerate low TRL investigations to underpin development of resilient materials innovations, enabling translation through to the Catapult network (NAMRC), TWI, international science programmes and laboratories (Halden Reactor, EUROfusion, Idaho National Laboratory, Japan Atomic Energy Authority, Department of Energy/PNNL, Australia’s Nuclear Science and Technology Organisation) and the nuclear industry (Rolls-Royce, Jacobs, EDF, and the Nuclear Decommissioning Authority Estate).

Dalton Nuclear Institute | World-leading research expertise and skills training in nuclear energy

Partner

This research theme brings together university expertise from The University of Manchester, and specialist centres NNL and UKAEA. Activity also takes place at Sheffield, Oxford and Imperial College London.

Equipment & Facilities

Scientists from the Nuclear Materials research area will in the Dalton Cumbrian Facility, a world-leading academic nuclear research capability in the UK. It provides a state-of-the-art base for high-end research in radiation science and engineering. NNL provides world-leading nuclear expertise into high neutron flux environments providing impartial advice to help shape the UK’s nuclear research agenda to enable the UK to be a top tier nuclear nation.